Digital twin technology is at the core of Industry 4.0, which enfolds automation, data exchange, and manufacturing processes, producing endless opportunities for industries to grow.

A digital twin is a virtual representation of a physical asset that is virtually indistinguishable from its physical counterpart. It includes design and engineering details that describe its geometry, materials, components, and behavior or performance. It is a key component of the Industry 4.0 ecosystem, owned and managed by business stakeholders to provide secure storage, processing, and sharing of data within an architectural tier.

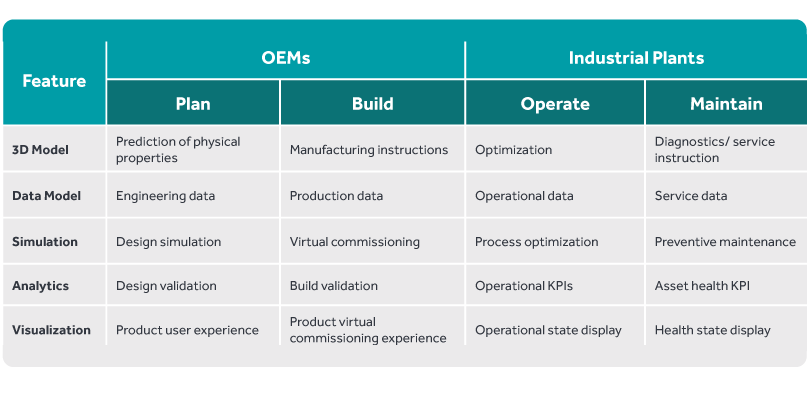

Industry needs intelligent and accurate predictive insights from sensor data to reduce unplanned downtime and enhance asset life. Digital twins can benefit the entire life cycle of industrial assets from the design to commissioning phases, and continue into operations.

Digital twin technology enables asset health monitoring and provides deeper analytical insights using thermodynamic, mathematical, and physics-based models. Further, it integrates these models with real-time and historical information from existing sensors.

Key value propositions include:

The growing adoption of Industry 4.0, which brings end-to-end value change with Industrial IoT and widespread digital transformation, is bringing a multitude of new technologies to the mainstream, including Digtial Twin.

Business benefits of a Digtial Twin:

Cyient has a global footprint, serving more than 11 different markets across the design, build, operate, and maintain spectrum.

Vehicle sensor data gives automotive OEMs and tier suppliers analytics from deployed fleets enabling OTA patching opportunities. Insurance providers adopting usage-based insurance (UBI) can leverage driver data for setting premiums and accident reconstruction.

Thousands of sensors on commercial planes stream asset data to better system servicing and operational status.

Connected medical systems and tools ensure product integrity and measure patient outcomes.

Digital factory equipment and machinery increase uptime and production yield, while reducing repair and maintenance rates.

Remote rigs send health data minimizing routine inspections and servicing.

View of deployed locomotives and assets health better optimizes scheduling, reducing servicing time.

Digital representation of systems on the power grid improves demand response functions and energy efficiency.

While digital technology is evolving rapidly and organizations are in a hurry to embrace it, early adopters need to be careful while defining their business strategies. They need to evaluate their maturity for processes, technology, and capabilities before they opt for technologies such as the twins.

Key considerations while working with a digital twin program:

Cyient (Estd: 1991, NSE: CYIENT) is a leading global engineering and technology solutions company. We are a Design, Build, and Maintain partner for leading organizations worldwide. We leverage digital technologies, advanced analytics capabilities, and our domain knowledge and technical expertise, to solve complex business problems.

We partner with customers to operate as part of their extended team in ways that best suit their organization’s culture and requirements. Our industry focus includes aerospace and defense, healthcare, telecommunications, rail transportation, semiconductor, geospatial, industrial, and energy. We are committed to designing tomorrow together with our stakeholders and being a culturally inclusive, socially responsible, and environmentally sustainable organization.

For more information, please visit www.cyient.com

Cyient (Estd: 1991, NSE: CYIENT)delivers Intelligent Engineering solutions for Digital, Autonomous and Sustainable Future

© Cyient 2024. All Rights Reserved.