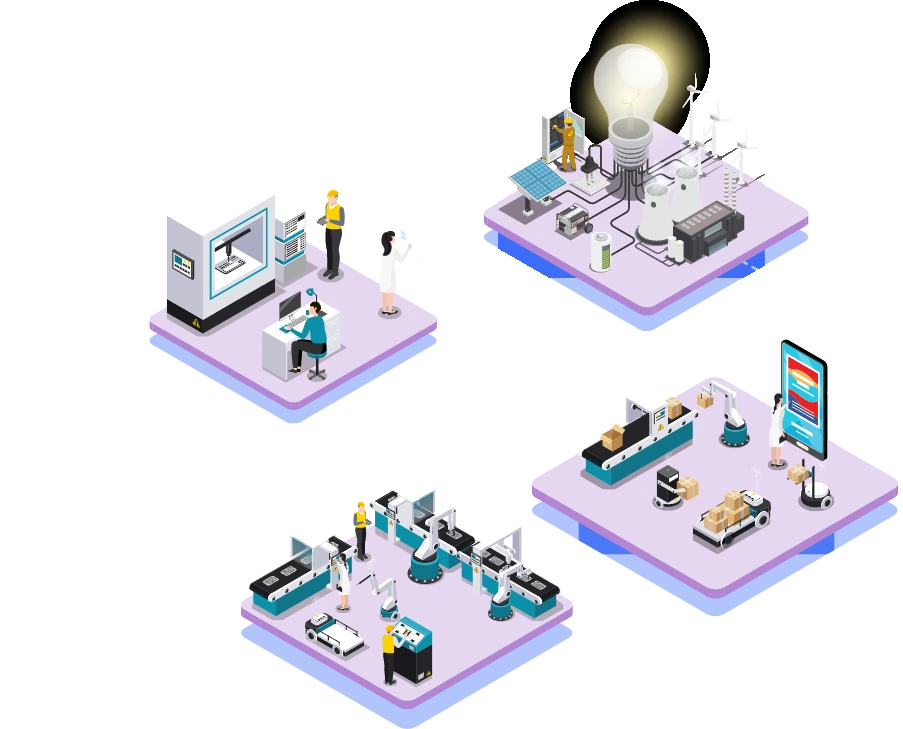

Enhance manufacturing efficiency, flexibility, and sustainability in a world of innovation, economic and regulatory pressures through the digitalization of assets, processes, and intelligence as a unified digital thread.

The rising customer expectations, fluctuating demands, and sustainability goals pose significant challenges for both discrete and process manufacturers. Overcoming these challenges can be difficult due to the lack of modern assets and a skilled workforce. Hence, manufacturing companies must intensify the digitalization of processes, machines, and day-in-life by adopting cutting-edge manufacturing technologies to improve processes and workforce performances.

Cyient MOM practice delivers an integrated digital thread approach to connect machines and devices, digitize processes, and bring intelligence as part of daily operations Our MOM services provide comprehensive coverage across Production, Maintenance, Quality, Batch, Health & Safety, Energy, and Connected Worker. It improves plant performance, asset utilization, product availability, and compliance adherence across sites and geographies.

01

Connect devices and machines to processes through intelligent controls, enable PLC/ DCS system integration, platform SCADA and Cloud maintaining security, standards, and compliances.

02

Create and maintain manufacturing data ecosystem on-premise and cloud for operations, machine, and process data through a plant information system, Historian, and IT-OT Integration.

03

Digitize operations and processes through MES and IIOT platform ecosystem across factories.

04

Manage asset performance through visual and mathematical analysis & prediction.

05

Bring intelligence to every process and day-in-life, enabled by real-time data and machine learning/AI.

Monitoring and predictive solutions for manufacturing assets to improve uptime and OEE.

Digitalize day-in-life at your factory floor across production, quality, maintenance, and workflows to improve performance and reduce cost.

Common data platform for machines and processes – factory network and/or factory cloud.

One-stop platform to monitor, analyze, and balance energy usage to optimize overall energy consumption and cost.

Digital platform for safety and health compliance integrated with manufacturing operations.

Asset visibility and intelligence to monitor asset health and upcoming failure mode.

Monitoring and predictive solutions for manufacturing assets to improve uptime and OEE.

Digitalize day-in-life at your factory floor across production, quality, maintenance, and workflows to improve performance and reduce cost.

Common data platform for machines and processes – factory network and/or factory cloud.

One-stop platform to monitor, analyze, and balance energy usage to optimize overall energy consumption and cost.

Digital platform for safety and health compliance integrated with manufacturing operations.

Asset visibility and intelligence to monitor asset health and upcoming failure mode.

Digitalization across ISA 95 layers

Roadmap-driven solutions aligned to the factory of the future

Intelligence as an integral part of daily operations

Safe, secure, and compliant on-cloud manufacturing, data, and operations

While scaling their business for the global market, large electronics manufacturing companies face several challenges including high cycle times, increased scrap, and lower production volumes. Cyient helped this manufacturing company implement Cantier MES with 9 different modules, which improved their productivity, efficiency, and the overall product quality.

When it comes to their shop floor operations, most businesses face challenges such as lack of transparency, health monitoring processes, and siloed databases. Cyient solved this by implementing an MES solution across four areas, performing business case and ROI analysis and scaling it to more lines and units.

A PCB manufacturer sought to improve product lifecycle management, performance monitoring, and asset analysis processes. Cyient’s unified data and digital thread empowered the manufacturer with a flexible and modular architecture and a unified structure for data, use cases, and integrations. This resulted in a 60% faster onboarding of new customers and a 15-20% system performance improvement.

.jpg)

Learn how connecting operational systems with enterprise platforms improves visibility, efficiency, and response times.

Industrial Data Fabric (IDF) Solution for smarter, faster decisions.

Converting Manufacturing Data Into Actionable Insights For Enhanced Decision Analysis

Cyient (Estd: 1991, NSE: CYIENT)delivers Intelligent Engineering solutions for Digital, Autonomous and Sustainable Future

© Cyient 2024. All Rights Reserved.