-

.jpg?width=1680&height=800&name=Frame%20120%20(2).jpg)

IN VITRO

IN VITRO

DIAGNOSTICS

(IVD)

Driving development

and growth of IVD

IVD encompasses a wide range of diagnostic technologies, including clinical chemistry, immunoassays, molecular diagnostics, and microbiology that form the foundation for successful treatments and patient satisfaction. With the constant evolution of testing mechanisms, pathological advancements, and technology integrations, this space can become a hotspot of innovation and growth - if one can overcome challenges like high cost of R&D, competitive market dynamics, and risk of failure at scale.

From complex and resource-intensive adaptation to changing regulations across regions to rapid technological advancements that impact system compatibility and increasingly difficult management of patient information amidst cyberthreats, there are plenty and pitfalls along the way. Cyient understands this predicament and embodies a brand promise to build IVD products that elevate the lives of the people. How? With cost-controlled innovations, accelerated time-to-market, and sustainable manufacturing that comply with industry standards.

Enhanced R&D efficiency and advanced technology integration to drive innovation and maintain a competitive edge.

Secured patient data integrity and ensured compliance with industry regulations through robust data management and lifecycle solutions.

Streamlined engineering and product costs with fast market entry to enhance resource efficiency and product delivery.

Optimized asset usage and reduced energy footprints with comprehensive manufacturing solutions and sustainability management.

Transforming Diagnostics with Intelligent Engineering

Cyient takes complete ownership in the end-to-end of the plant engineering lifecycle, from feasibility analysis to operations and maintenance. We have successfully delivered over 1000 power plant projects globally, leveraging more than 30 years of industry expertise and best practices.

.jpg?width=838&height=353&name=Mask%20group%20(24).jpg)

- Concept Generation

- Detailed Design

- Verification & Validation

- Prototype Development

- Product Documentation

- Design Transfer

.jpg?width=838&height=353&name=Mask%20group%20(25).jpg)

- Remediation

- Corrective action/Preventive action

- QMS Development

- Product design Control

- Superior Quality Assurance Services

- QSR Compliance with 21 CFR 820

.jpg?width=838&height=353&name=Mask%20group%20(26).jpg)

- IVDR & MDR Compliance

- Country specific regulatory filings and submissions

- Environmental compliance (RoHS, REACH, WEEE)

- Risk management services per ISO 14971

- Responding to FDA 483 observations, warning letters, and Notified Body audit findings

- Post Approval Change Control

.jpg?width=838&height=353&name=Mask%20group%20(27).jpg)

- FHIR

- Connected Care

- SaMD

- IoMT

.jpg)

- Concept Generation

- Detailed Design

- Verification & Validation

- Prototype Development

- Product Documentation

- Design Transfer

.jpg)

- Remediation

- Corrective action/Preventive action

- QMS Development

- Product design Control

- Superior Quality Assurance Services

- QSR Compliance with 21 CFR 820

.jpg)

- IVDR & MDR Compliance

- Country specific regulatory filings and submissions

- Environmental compliance (RoHS, REACH, WEEE)

- Risk management services per ISO 14971

- Responding to FDA 483 observations, warning letters, and Notified Body audit findings

- Post Approval Change Control

.jpg)

- FHIR

- Connected Care

- SaMD

- IoMT

In the Spotlight

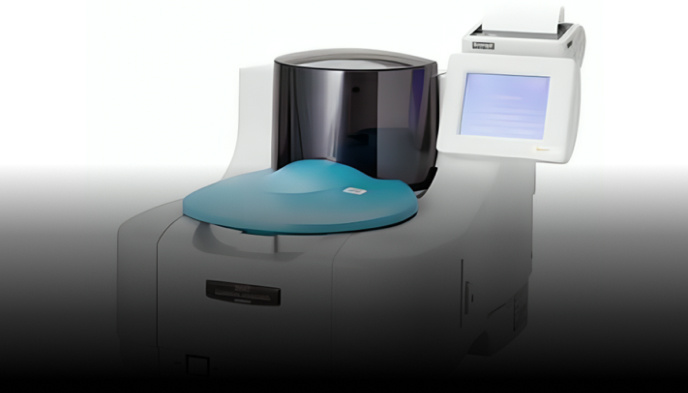

Developed New Product- Clinical Analyzer

Revamped architecture, motherboard, and 11 child boards, mitigating obsolescence. Achieved 20% cost reduction, crafted and tested all boards. Produced 5 prototypes, tailored for Indian manufacturing localization.

.jpg)

Point of Care IVD System

Developed a rapid POC real-time PCR diagnostics system for infectious diseases, implementing specialized production lines for efficient manufacturing. Achieved quick production ramp-up and cost reduction, ensuring competitive manufacturing costs.

-1.jpg)

Sustenance Engineering for Anatomical Pathology Diagnostic

Built the transfer system for automatic slide stainer to cover slipper for automation in the two downstream processes in a pathology laboratory under sustenance program with our CoE client

.png?width=774&height=812&name=Master%20final%201%20(1).png)