Industry 4.0: Tools for Speed, Certainty, and Stability Now and Post-COVID-19 (Part 1 of 2)

Written by Adam Erdesky 30 Apr, 2020

In this two-part blog series, we discuss how Industry 4.0 tools are being leveraged to survive market disruption.

The relevance of Industry 4.0 is growing as we face a global pandemic today. With every business impacted by this disruption in one way or another, industries are reflecting on 2020 as a significant inflection point in global operations. Every major disruptive shift throughout history—whether driven by pandemic, disaster, or technological change—has winners and losers. The firms best positioned for survival and growth today are focusing on:

- Agility: Capability to internalize market signals and adapt processes in response

- Digital: Investment in modern systems, data analytics, and decision support

- Risk Management: Evaluation and mitigation of potential operational/ financial impacts

Now and after the COVID-19 crisis, business-as-usual is being replaced with a new landscape embracing remote connectivity and digital technologies. But what really is this “new normal,” and which tools will help companies sustain difficult times and rebound?

New Normal 1: Virtual communications

With global travel restrictions in place and employees under lockdown in their homes, businesses are forced to communicate remotely with their manufacturing operations, supply chain partners, and customers. Digital tools and advanced networks have allowed companies to adapt to the circumstances more quickly than we could have imagined. As firms have been forced to test and embrace distributed work structures, we will likely see continued adoption and extension of remote connectivity options long into the future, saving time and cost.

New Normal 2: Transparency and access to real-time data

Global supply chain networks have been under stress as businesses adapt to supply shortages, add capacity for essential products, or reconfigure production to react to changing demands. Companies must be robust to this dynamic environment, with little room for trial and error. Accurate and reliable data inputs and outputs are essential for faster response by decision makers, and ensure that investments are allocated with appropriate economic priority.

New Normal 3: Data-driven decision-making

While almost every company recognizes the value of using data for tactical and strategic insights, many fail to realize the full benefit of their data. Improved speed and certainty of decisions enabled by ML, AI, and advanced analytics will provide valuable direction and enable data-driven firms to survive in tough times and rebound in recovery.

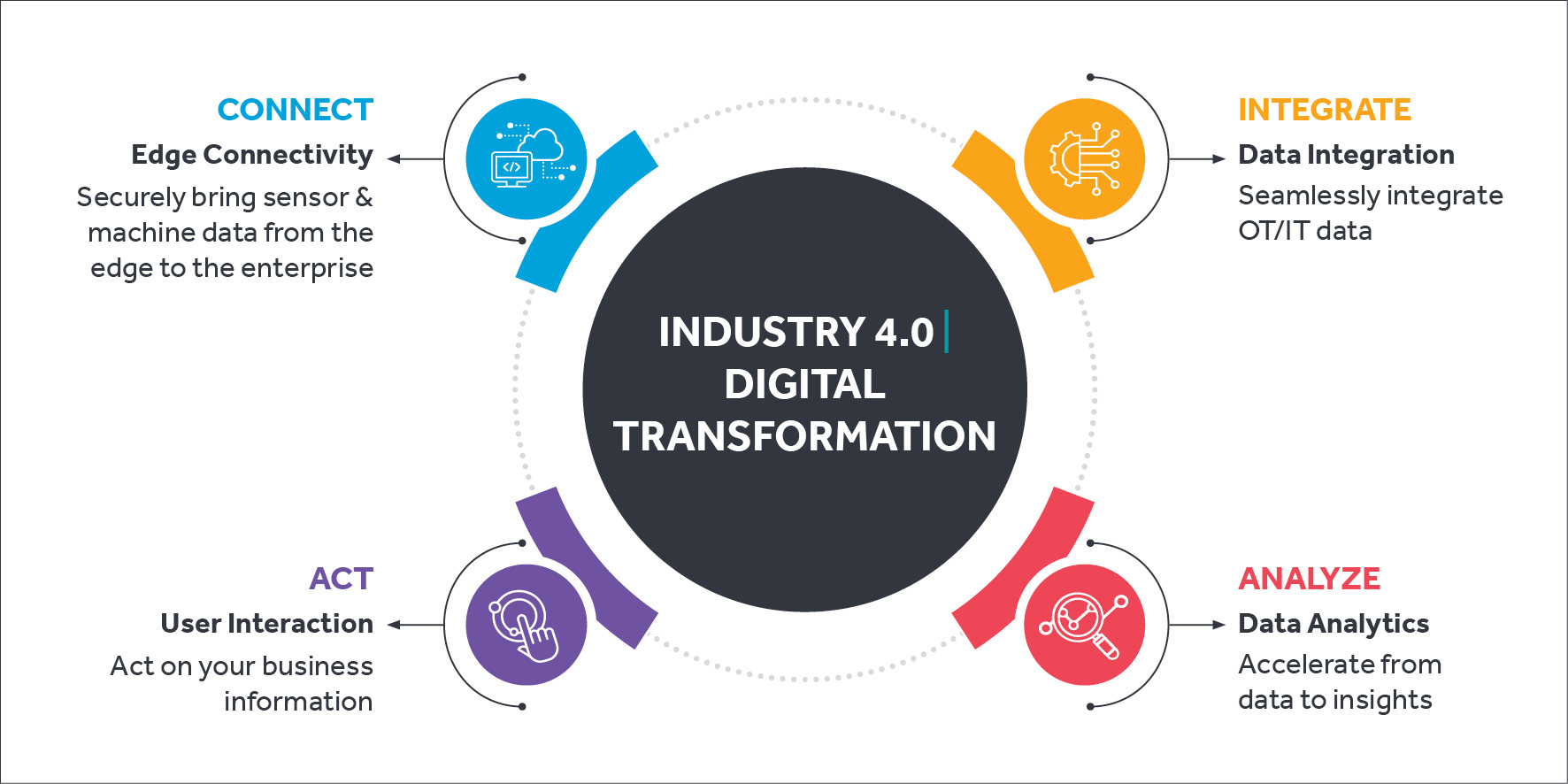

What Industry 4.0 tools are companies using to adapt, react, and stay connected with their manufacturing operations, supply chain, and customers?

Tools to CONNECT

- Capture and transmission of streaming Industrial IoT sensor and machine data

- Intelligence at the edge: gateway devices analyze and act in real-time

- Smart asset tags and trackers help manage raw material and work-in-process assets throughout production, as well as finished goods, equipment, vehicles in the field

Tools to INTEGRATE

- Modern cloud and on-premise data management architectures

- Ingest of streaming data; integration of multiple enterprise sources

- Data engineering: manage big data, data lakes, ETL pipelines, and data warehousing

Tools to ANALYZE

- Advanced analytical models to identify patterns, relationship, trends, or anomalies to develop deeper insights, predict behaviors, and recommend preventative actions

- Training and deployment of machine learning models tools to parse relevant information from unstructured or semi-structured data

- Deep learning and AI algorithms for image analytics, natural language inference, and other feature extraction applications to enable automation and reduce time-to-insight

Tools to ACT

- Interaction and interpretation of information through dynamic BI visualization tools, dashboards, and customized reporting

- Responsive web and mobile apps to integrate with your business processes and workflows

- Immersive, interactive tools including augmented and mixed reality technologies, digital twin simulation, and chatbots

Industry 4.0 tools have proven to offer immense value to those who adopted them, even without express anticipation of a pandemic. Companies that delayed investment in digital transformation are being forced to revisit their strategies and implementation roadmaps, as more modern and lean competitors enjoy a relative advantage in their crisis response. Many firms—whatever their industry, size, and technology posture—are beginning to realize that the end of the crisis may not be accompanied by a return to business-as-usual.

Part II of this blog series will provide insights on “How Smart Factories Stay Connected During a Lockdown”. Stay tuned.

Learn more about our digital capabilities.

.png?width=774&height=812&name=Master%20final%201%20(1).png)