AI in Battery Recycling: Strides in Sustainability

Written by Shyam Sundar Pal 03 Jan, 2024

In recent times, there has been a significant shift in vehicle propulsion, moving away from traditional fuel combustion engines to battery-driven systems. These batteries are predominantly of the lithium-ion variety, composed of various rare metals and minerals. However, the extraction and processing of these materials incur substantial economic and environmental costs. The excessive mining of rare elements and improper battery disposal also negatively affect the environment.

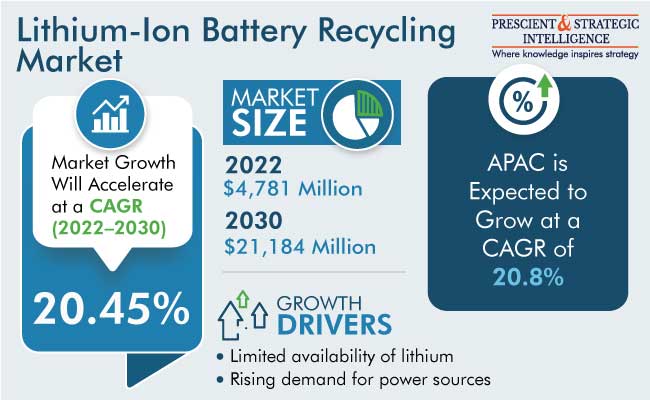

Consequently, the production of new batteries using raw metals and minerals results in escalating manufacturing costs. There is a pressing need to recycle rare elements from spent batteries to work toward a more sustainable future. This reduces manufacturing costs and minimizes the environmental impact associated with battery disposal.

Achieving effective recycling and sorting of these rare materials requires an intelligent and efficient mechanism. This can be realized by implementing artificial intelligence (AI), utilizing intelligent, automated processes. AI standardizes various stages of battery recycling, incorporating predictive analysis of data points. The analytical steps encompass data point collection, predictive battery charging analysis for extending battery life, and the recovery of materials from disposed batteries.

The integration of robotic automation with AI facilitates the safe, efficient, and economical recovery of materials from used batteries. Ongoing extensive research and initiatives are actively exploring the intersection of battery recycling and AI. Notably, the World Economic Forum's (WEF) Global Battery Alliance has initiated a project focused on a "battery passport" platform. This platform aims to analyze battery material, mineral, and chemical properties, assess battery life, and scrutinize the manufacturing processes involved. These efforts are a significant step toward a more sustainable and environmentally conscious approach to battery production and disposal.

Benefits of Battery Recycling

The exponential surge in battery manufacturing, driven by the increasing demand for electric vehicles and other applications, has inevitably resulted in the generation of chemical waste. Effectively managing this waste is crucial, and its disposal should be designed to facilitate material recycling for subsequent use as raw materials.

The advantages of recycling materials from disposed batteries are multifaceted, encompassing critical aspects:

- Critical materials preservation: Recycling enables the conservation of critical materials, which are often rare and essential components of batteries. By recovering these materials, we mitigate the risk of depletion and ensure a sustainable supply for future manufacturing needs.

- Integration into the production supply chain: The recycled materials can be seamlessly reintegrated into the production supply chain. This reduces the reliance on virgin resources and contributes to a circular economy where materials are reused, minimizing the demand for new extractions.

- Ecological balance: Recycling batteries plays a pivotal role in maintaining ecological balance. It curtails the environmental impact associated with the extraction of raw materials, reducing the need for extensive mining and lessening the strain on ecosystems.

- Reduced carbon footprint: One of the significant benefits of recycling materials from disposed batteries is the reduction in carbon footprint. The conventional process of extracting and processing raw materials for battery manufacturing is energy-intensive. Recycling substantially reduces these energy requirements, lowering the overall carbon emissions associated with battery production.

Adopting comprehensive recycling practices aligns with sustainability goals, fostering a responsible approach to the burgeoning battery industry. By prioritizing material recovery and integrating it into the production cycle, we not only address environmental concerns but also pave the way for more efficient and sustainable use of resources in the era of expanding electric vehicle adoption.

AI Battery Waste Management and Recycling

AI is a crucial enabler in establishing a streamlined and intelligent system for efficiently collecting battery waste, leveraging advanced image processing techniques. Through analysis of captured images, the system discerns the type and volume of the battery waste, facilitating a meticulous sorting process. Implementing an intelligent and efficient mechanism for sorting battery elements is made possible through the seamless integration of AI algorithms.

Battery waste sorting

The sorting of battery waste is executed through predictive analysis, focusing on chemical component data. AI algorithms play a pivotal role in discerning various battery types, employing predictive analysis to extract essential battery elements. Intelligent and automated sorting systems for battery materials enable swift and precise sorting of crucial components. Systems equipped with intelligent features like AI offer a mechanism for identifying and segregating diverse battery types and chemicals efficiently. This not only enhances the speed of the sorting process but also ensures the accuracy of categorizing essential battery materials.

Battery waste processing

Battery waste can be categorized into two main types:

- Battery aging: When a battery remains unused for an extended period, it undergoes a discharge process, rendering it incapable of further charging and utilization. In this state, the battery has reached the end of its functional life due to prolonged inactivity.

- End of life (EOL): The second classification arises when a battery has been actively used, and its cells no longer retain the capacity for additional charging and usage. In this scenario, the battery has reached its end of life (EOL) as the cells have depleted to a point where sustained functionality is no longer viable.

In both these cases, the common outcome is that the battery is deemed unfit for continued use and is disposed of. However, rather than becoming an environmental burden, these disposed batteries can be repurposed through recycling initiatives, contributing to sustainable practices and resource conservation. Recycling aims to extract valuable materials from discarded batteries, mitigating the environmental impact of their disposal.

AI Analytics in Battery Recycling

AI analytics is pivotal in optimizing various facets of battery usage, production, and recycling, particularly in the context of electric vehicles (EVs). It enhances the efficiency of battery manufacturing and supports the recycling chain for EV battery production. Prescriptive analytics emerges as a cost-efficient solution specifically tailored for optimizing the quality and throughput of an EV battery production line. This sophisticated approach extends its benefits to bolstering the recycling dimension within the EV battery-making process.

AI analytics employs a deep learning mechanism to process data points acquired during battery sorting. Modern battery manufacturing extensively relies on AI analytics to maximize the utilization of production residuals, contributing to the supply chain of raw materials for battery manufacturing. Collaborating with data scientists, battery manufacturers identify critical components and parameters in the recycling process. This involves a meticulous check to ensure the presence of these parameters. This collaborative method efficiently recovers essential battery components such as lithium, nickel, cobalt, and manganese during the recycling process.

Creating Sustainable Tomorrows

The highlighted approach emphasizes the significance of using AI in optimizing battery recycling processes and segregating critical battery components. Several AI-driven analytics solutions tailored to diverse applications within battery waste management and recycling are available in the market, showcasing the versatility and adaptability of AI technologies in advancing sustainable practices.

With the rising demand for EVs, recycling their batteries emerges as a key component in mitigating environmental impact and ensuring resource efficiency. The integration of AI analytics in the battery recycling process has proven instrumental in optimizing the production, usage, and recovery of essential components. Through prescriptive analytics and deep learning mechanisms, the industry is streamlining EV battery manufacturing and contributing significantly to the circular economy by efficiently recovering materials. As we navigate toward a future dominated by electric mobility, the responsible management of EV battery waste through innovative technologies and collaborative efforts remains paramount for a sustainable and greener tomorrow.

About the Author

Shyam has 18 years of experience in IT industry and academics with an extensive knowledge in design, development and testing of software products in Automotive and Telecom. He is currently engaged in developing Software Defined Vehicles (SDV) and Model-Based Software Design (MBD). He developed the architecture and led the team for development of navigation stack for self-driving vehicles. His technical expertise includes development of Base Software and Application Software of Classic Autosar. Shyam holds 27 granted patents in the area of self-driving vehicle navigation stack, path planning, mapping and wireless 4G LTE & 5G.

.png?width=774&height=812&name=Master%20final%201%20(1).png)