Prioritizing Road Safety in Mines

Written by Diptesh Vijaysingh Kadam 13 Jul, 2023

Mines play a crucial role in the extraction of valuable resources, but they are inherently hazardous environments. While safety measures are typically focused on the operational aspects of mining, one crucial area that often gets overlooked is road safety within mines. The transportation of personnel, equipment, and materials along the complex network of mine roads presents significant risks. It is imperative to prioritize road safety within mines to minimize accidents, protect lives, and ensure sustainable mining operations.

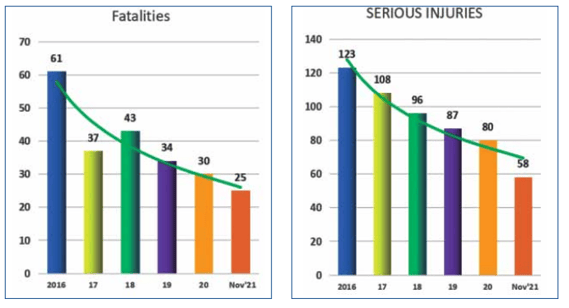

Trend of Five-Yearly Average Fatalities and Injuries in Coal India Limited since 1975

Table 1. Frequency of mining industry fatalities in USA, by major event group, age 16 years and over, 2004-2008

Event |

Frequency |

Percent |

Transportation |

326 |

37.82 |

Contact with objects/equipment |

291 |

33.76 |

Fires and explosions |

96 |

11.14 |

Exposure to harmful environments |

78 |

9.04 |

All other events |

71 |

8.24 |

Total |

862 |

100.00 |

Source: - U.S. BUREAU OF LABOR STATISTICS ( https://www.bls.gov/opub/mlr/cwc/transportation-fatalities-in-the-mining-sector-20042008.pdf )

The article has underlined the significance of road safety in mines and the need to explore strategies for ensuring a secure working environment underground.

Road Safety Challenges in Mining

- Limited visibility and confined spaces: Mine roads are often narrow, winding, and located in confined spaces, making it challenging for drivers to maneuver safely. Limited visibility due to dust, low lighting, or the presence of heavy machinery further adds to the risks.

- Uneven and unstable road conditions: Mine roads are subjected to heavy loads and continuous wear and tear. The rough terrain, loose surfaces, and frequent use of heavy equipment can cause road surfaces to become uneven, making them more prone to accidents and vehicle rollovers.

- Interaction with heavy machinery: Mines are bustling environments where various types of equipment and vehicles coexist. The interaction between trucks, loaders, excavators, and other machinery poses a significant risk to road users if not managed effectively.

- Exposure to hazardous materials: Certain mining operations involve transporting hazardous materials such as chemicals or explosives. Accidents involving these substances can have severe consequences, not only for road users but also for the surrounding environment.

Strategies for Safer Operations

The mining industry relies heavily on transportation infrastructure to move personnel, equipment, and materials within vast and complex sites. In this high-risk environment, ensuring road safety is not just a legal obligation but a moral responsibility. Effective road safety practices in mines not only protect the lives and well-being of workers but also contribute to increased productivity and sustainable operations.

- Comprehensive training programs: Effective road safety begins with comprehensive training programs for all personnel involved in underground operations. Workers, drivers, and equipment operators should receive proper training on safe driving techniques, traffic rules, and hazard recognition. Regular refresher courses and continuous training updates should be provided to reinforce road safety awareness and ensure compliance.

- Robust traffic management plans: Developing and implementing traffic management plans are crucial to minimizing the risk of mine accidents. These plans must include speed limits, signage, and standardized road designs to optimize traffic flow. Clear and visible markings should be present to guide drivers and pedestrians, and designated parking areas should be established to avoid congestion. Regular audits and assessments should be conducted to identify and rectify any shortcomings in the traffic management system.

- Regular inspections and maintenance: The condition of roads and associated infrastructure must be regularly inspected and maintained in mines. Uneven surfaces, potholes, and inadequate lighting can pose significant risks. Routine inspections, prompt repairs, and preventive maintenance ensure that the road network is safe and well-maintained. Additionally, proactive measures such as implementing drainage systems and controlling dust levels can contribute to safer road conditions.

- Vehicle safety standards: Vehicles used in mining operations should meet stringent safety standards. Regular inspections and maintenance of vehicles, including brakes, lights, tires, and warning systems, are vital. Seat belts must be functional and worn at all times, and vehicles should be equipped with fire extinguishers, first aid kits, and communication devices. Strict adherence to vehicle load limits and avoiding overloading are crucial to maintaining stability and preventing accidents.

- Technology and automation: Advancements in technology can play a significant role in enhancing road safety in mines. Installing proximity detection systems, collision avoidance systems, and real-time monitoring devices can help mitigate the risk of accidents. Autonomous vehicles and remote-controlled machinery can also reduce the presence of workers in hazardous areas, minimizing the potential for incidents.

Tech Solutions

By implementing comprehensive measures, mine operators can significantly reduce accidents, injuries, and fatalities. Solutions encompass a range of strategies, including advanced vehicle technologies, rigorous training programs, improved infrastructure, enhanced visibility and communication systems, and strict adherence to safety regulations. Here are a few of our recommendations to increase road safety in mines:

- Efficient routing: Site Router-Public v Private Road Integration helps optimize route planning within and outside of the mining area. This is a single-window solution to visualize and track all mine vehicles. Private road editors like mine operators or authorized persons can add new road geometry and road attributes such as type, speed, gradient, etc., and notifications on the live maps.

- Sensor integration: Sensor mounted on vehicles would be collecting real-time data such as temperature, humidity, speed, rain, air quality, noise levels, energy consumption, etc., for intelligent decision-making and reporting. The data from the sensors can be integrated with dashboards, and can provide geofence alerts and notification of driving habit in back office.

- System integration: Sensor data integration with existing systems such as SAP, Maximo, and ERP allows seamless reporting for regulatory compliance audits.

Safety-Productivity Equation

Road safety in mines is imperative for maintaining a secure work environment and protecting lives below the surface. By implementing comprehensive training programs, developing robust traffic management plans, conducting regular inspections and maintenance, adhering to vehicle safety standards, and leveraging technology, mine operators can significantly mitigate the risk of road accidents. Ensuring road safety not only protects the workforce but also enhances operational efficiency and productivity. By prioritizing road safety, the mining industry can continue to profit while safeguarding the well-being of its most valuable assets.

How Cyient Contributes in Ensuring Road Safety of Mine Operators?

If you operate a fleet of vehicles then there’s a good chance that you would need Last Mile Connectivity solution (LxC). This isn’t limited to Delivery, but includes field operations of every kind. Cyient works with leading platform and data providers to implement fleet route planning, adding new routes and optimisation services. Cyient collaborates with key platform and data providers to deliver fleet route planning, route expansion, and route optimisation services. Cyient Site Router - Public vs Private Road Integration LxC module that works for customers whose roads are owned and managed by private entities such as mines or ports. Some of these roads are constantly changing and Cyient's Public and Private Road Integration service assists businesses in creating a seamless transition from private to public roadways, both in terms of planning and navigation.

.png?width=747&height=618&name=MicrosoftTeams-image_(15).png)

About the author

Diptesh Vijaysingh Kadam is a gold medalist in geology from The Maharaja Sayajirao University of Baroda. He has 16+ years of industry experience, which includes 10 years in the O&G industry. His expertise spans surveying, planning, designing, and overseeing operations and maintenance of pipelines. His areas of interest are building end-to-end geospatial solutions for oil and gas pipelines for better and safe operations.

.png?width=774&height=812&name=Master%20final%201%20(1).png)