-

.jpg?width=1680&height=800&name=Frame%20120%20(9).jpg)

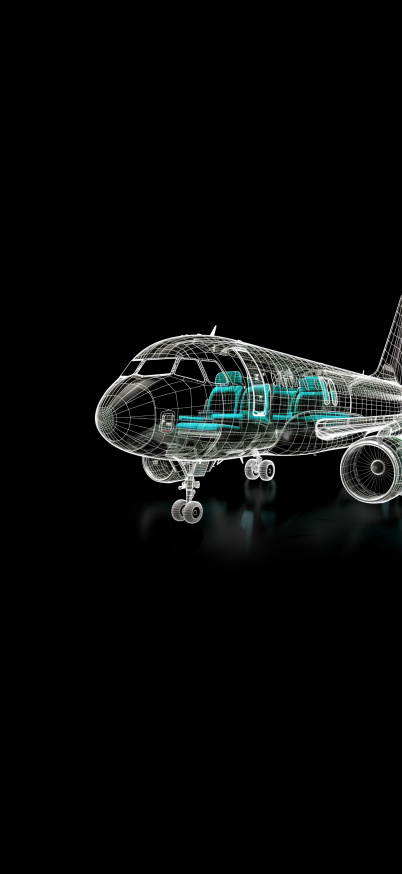

AERO

AERO

STRUCTURES

Innovative Structural Design for Optimized, Safer, and Efficient Aircrafts

With customer-specific design processes, extensive knowledge of metallic and composite material, value engineering, and design automation to create cost-effective structures. Being a trusted risk-sharing partner for global OEMs and Tier 1 suppliers for more than 20 years, we help accelerate time-to-market with end-to-end services from conceptual design, program management, preliminary design, stress analysis, and report delivery for certification with authorities to post-production.

Design, Analysis, Testing & Certification

Design, analysis, and testing knowledge acquired by collaborating with global OEMs and Tier 1 Suppliers.

Aftermarket Value Streams

Structural repair engineering, refurbishment & change incorporation, retrofit designs, reverse engineering, and P2F conversion.

Manufacturing Non-Conformance

Innovative solutions in evaluating manufacturing non-conformances and providing MRB support in Design & Stress dispositions meeting regulatory compliance like FAA, EAS, and more.

AS9100C and CEMILAC Certifications

Certifications for airframe structures and aircraft assembly tool design and engineering.

Intelligent Engineering

with Cyient

-1.png)

STRUCTURES

DESIGN (METALLIC

& COMPOSITE)

Enabling Design, Stress Analysis, FEM Simulation, Kinematics, Full 3D MBD for manufacturing requirements, Fatigue & Damage Tolerance Analysis, FOD Analysis, Certification reports, Weight optimization for complete airframe.

-1.png)

KNOWLEDGE-

BASED

ENGINEERING

(KBE) TOOLS

Developing automated solutions for repetitive engineering tasks.

-1.png)

REVERSE

ENGINEERING

Conducting design, stress analysis, prototype build, testing and certification per FAA / EASA regulations.

-1.png)

END-TO-END

AIRCRAFT

STRUCTURES

LIFE CYCLE

MANAGEMENT

Ensuring design, analysis, testing, certifications, maintenance and aftermarket services.

-1.png)

DESIGN DATA

CONVERSION

AND DIGITALIZATION

SERVICES

Performing data conversion for structures, systems, and composites from Catia V4 to V5, Mylar 2D drawings to 3D, Model-based design-MBD.

Insights

Bolstering Structural Stability and Reliability of Aircraft Systems

Read more on how Cyient’s F&DT analysis for metallic and composite airframe parts helps ensure complete safety across pre- and post-manufacturing cycles.

Bird Strike Simulation Analysis for Enhanced Passenger and Financial Safety

Discover how smart simulation can help manufacturers prepare for bird strikes beforehand and significantly reduce testing costs.

.png?width=774&height=812&name=Master%20final%201%20(1).png)