-

.jpg?width=1680&height=801&name=Frame%20120%20(2).jpg)

AERO SYSTEMS

AERO SYSTEMS

& AVIONICS

India's Leading Avionics Innovator: Delivering State-of-the-Art Avionics Systems for Safer and Better Aircraft

Engineering solutions from requirements definition to avionics certification

Avionics certification for all Design Assurance Levels (DAL) A to E

Compliance with FAA and EASA standards

Integration of technologies like AI and IoT

Intelligent Engineering

with Cyient

.jpg)

POWER

SYSTEMS

NAVIGATION AND

SYSTEMS

Engineering efficient and highly reliable solutions for aerospace and defense guidance, targeting, and avoidance systems.

COMMUNICATIONS

SYSTEMS

Developing digital, analog, Radio Frequency (RF), microwave, and signal processing electronics for aircraft communication systems.

FLIGHT CONTROL

SYSTEMS

Crafting embedded software and electronic hardware design solutions for fly-by-wire systems, actuation systems, collision avoidance, and autopilot controls.

Intelligent Surveillance and

Reconnaissance (ISR)

Real-time critical intelligence gathering and surveillance combined with data processing, exploitation, and dissemination solutions.

In the Spotlight

CyientfIQ High Voltage DC to DC Converter

Explore how we build a converter that offers a superior alternative to distributing power at low voltage over long distances with CyientfIQTM.

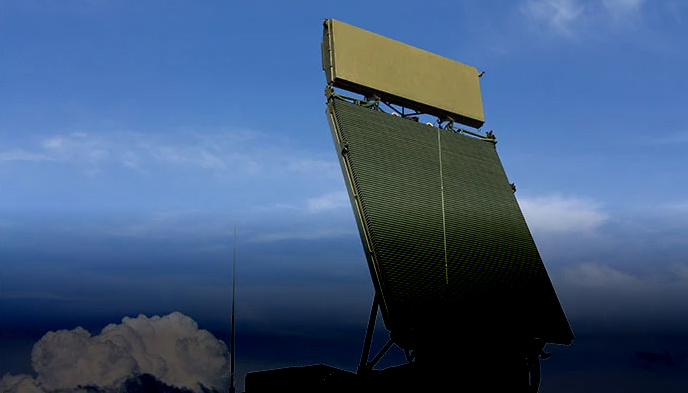

Transmit and Receive Module

Discover how we automate product processes and exercise offset obligations with Cyient’s X-Band Transmit and Receive Module for radar applications.

Common Automated Testing Equipment

Read how we conduct tests with faster turnaround time and expanded coverage with our Automated Testing Equipment (ATE).

ARINC 429 IP CORE FOR FPGA

Find out how we ensure increased reliability and build a DO-254-compliant offering with a multichannel ARINC 429 transmitter/receiver core.

Software Defined Radio

Learn about India’s first indigenous manpack SDR for secure and reliable military communications systems.

Dedicated Labs

Digital Lab

Lab Equipment, tools, and simulators to enable development of high-speed Boards (Analog, Digital, Mixed & RF), FPGA, Processors, LRU level test set up

Power Electronics Lab

Lab equipment to enable development of power products up to 22.5 kVA (DC-DC Converters, Inverters, Power Distribution Boxes, Actuation, Battery Management etc.

RF and Comms Lab

Calibrated test equipment and simulation tools to enable development of navigation, radars, communication systems up to <26.5 GHz

Insights

Verification and Validation of Field Programmable Gate Arrays

Learn how to wade through key technical challenges in aerospace V&V and build a successful global partnership model for FPGA verification and validation

Adaptive Sliding Mode Controller for Stable DC Microgrids

Explore strategies to enhance the stability of a system that is connected to a constant power load(CPL).

Embedded Software Testing Challenges & Solutions

Find out about embedded software types, how to test them, and automate them to improve test coverage and reduce time-to-market.

.png?width=774&height=812&name=Master%20final%201%20(1).png)