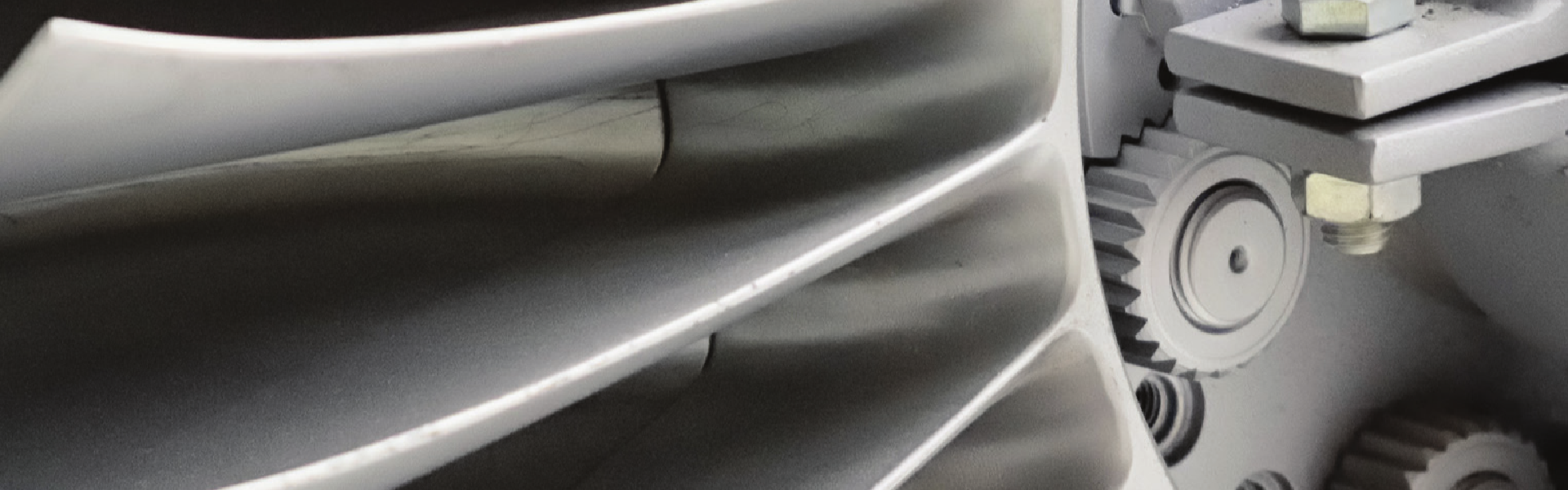

Gas turbines are a fascinating blend of engineered functionality and technological art, producing power relentlessly as air sweeps through the aerodynamic profile of each blade.

This technology is swiftly evolving as manufacturers are advancing through aero-derived studies. In the recent years, they had brought in the full weight of their research and development to bear on several design, performance and efficiency goals. There is a tremendous effort towards increased fuel efficiency, minimizing carbon footprint, and reduce noise levels.

In this article, an effort is made to summarize the evolving advancements in Turbomachinery while giving an overview of achievements in past decades.

The aviation sector is growing fast and will continue to grow. The most recent estimates suggest that demand for air transport will increase by an average of 4.3% per annum, meaning a doubling in the next 20 years.

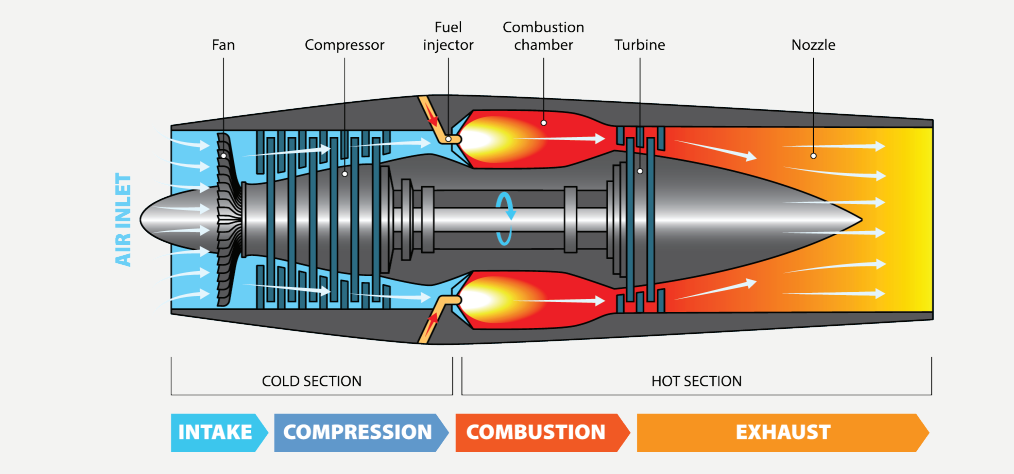

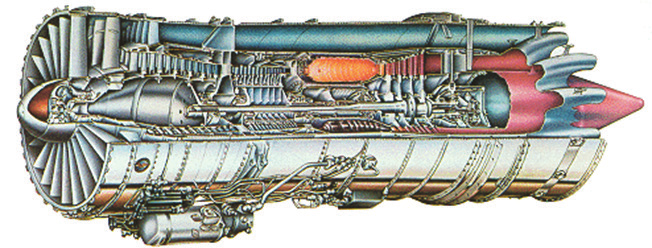

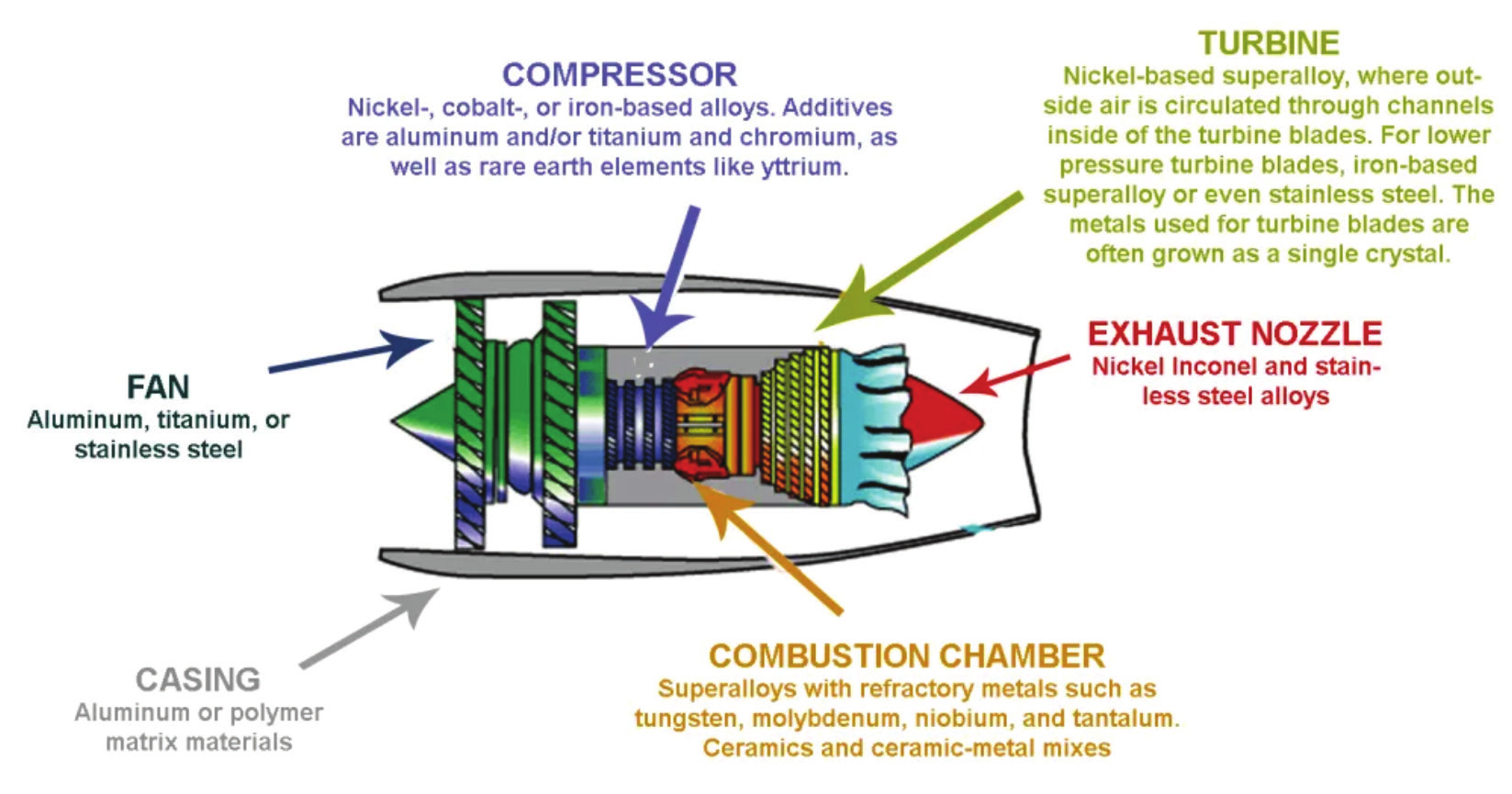

Gas turbines are used to power the aircrafts. They convert the internal energy of a fluid (temperature or pressure) into kinetic energy (velocity). The air ingested by the gas turbine is passed through a compressor, which raises its temperature and pressure. By burning fuel in the combustor additional energy is added to the compressed air. Part of this energy is recovered through a turbine to drive the compressor and the engine auxiliary equipment. The remaining energy is available to form a propulsive jet, which can be used to push forward an aircraft, like in a jet engine, or to drive a turbine to make power available on a shaft, like in a ship or in a power station. Figure 1 shows the stages of a typical gas turbine.

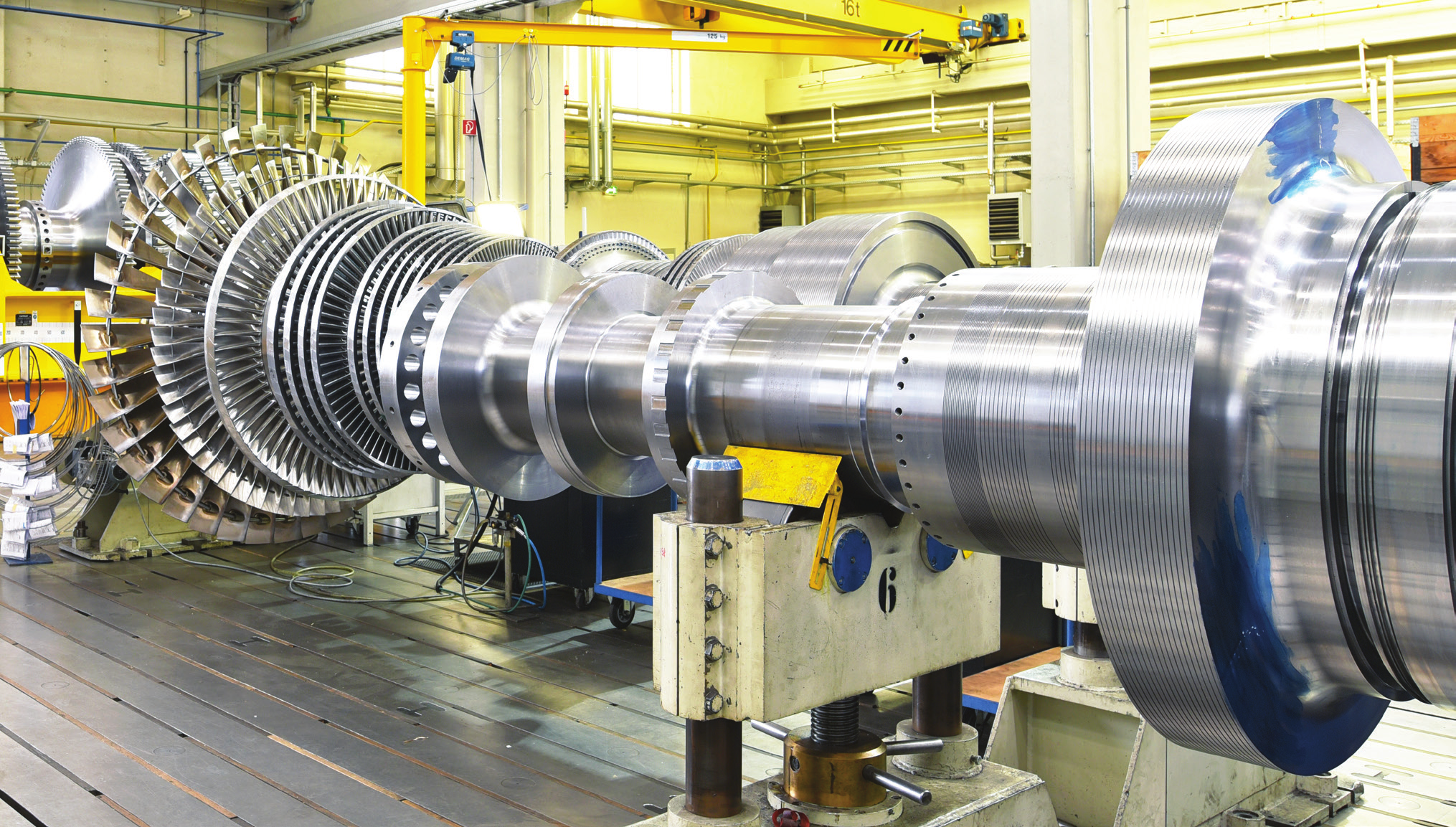

Components of a gas-turbine must be carefully designed and manufactured from costly materials because of the high temperatures and stresses encountered during operation. Historically it was the difficulty of designing efficient compressors, even more than efficient turbines that delayed the development of the gas-turbine engine. Modern units can have compressor efficiencies of 86–88% and turbine efficiencies of 88–90% at design conditions. Early gas turbines employed centrifugal compressors, which are relatively simple and inexpensive.

They are, however, limited to low pressure ratios. This led to the development of modern axial-flow compressors. However, the bypass ratio (BPR) is low which has a direct impact on fuel efficiency. Further advances led to development of Geared Turbofan (GTF) technology, which resulted in higher bypass ratio (BPR). The Geared Turbofan is a type of turbofan engine, with a gearbox between the fan and the low-pressure shaft to spin each at optimum angular velocities. Next two decades will see more focused advancements in this technology leading to enhanced GTF derivatives.

Figure 1: Gas Turbine working schematic

Figure 1: Gas Turbine working schematic

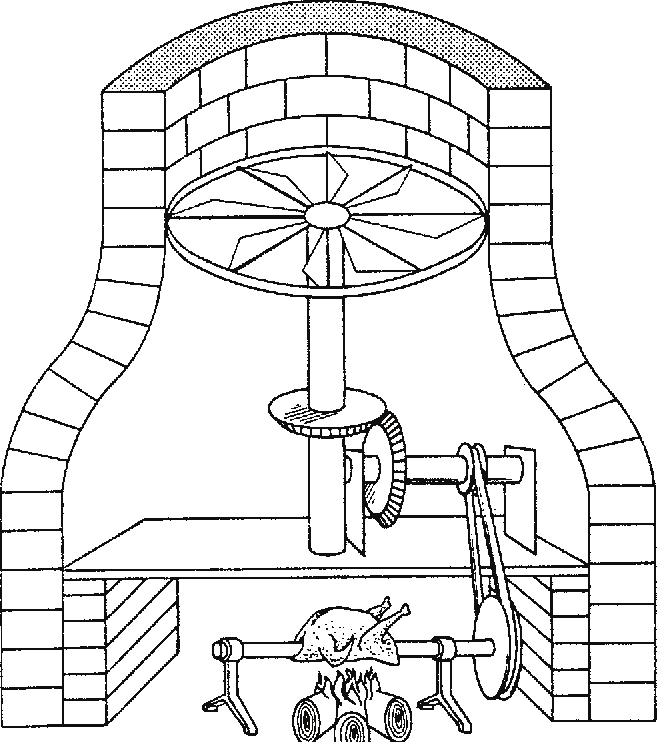

The earliest device for extracting rotary mechanical energy from a flowing gas stream dates back to 1500s. It was the windmill followed by the smoke jack (Figure 2).

During the mid-1930s a group headed by Frank Whittle at the British Royal Aircraft Establishment (RAE) undertook efforts to design an efficient gas turbine for jet propulsion of aircraft. Whittle’s designs were based on centrifugal compressor which has favorable characteristics for small mass flow rates, but they become less efficient when the machine is scaled up to power a bigger aircraft. This engine was more suited than piston engines for high altitude and high-speed flight.

Independent parallel developments in Germany, initiated by Hans P. von Ohain working with the manufacturing firm of Ernst Heinkel, resulted in a fully operational jet aircraft engine that featured a single centrifugal compressor and a radial-inflow turbine. This engine was successfully tested in the world’s first jet-powered airplane flight on Aug 27, 1939.

Figure 2: Chimney Jack Conceived by Leonardo Da Vinci (1500 AD)

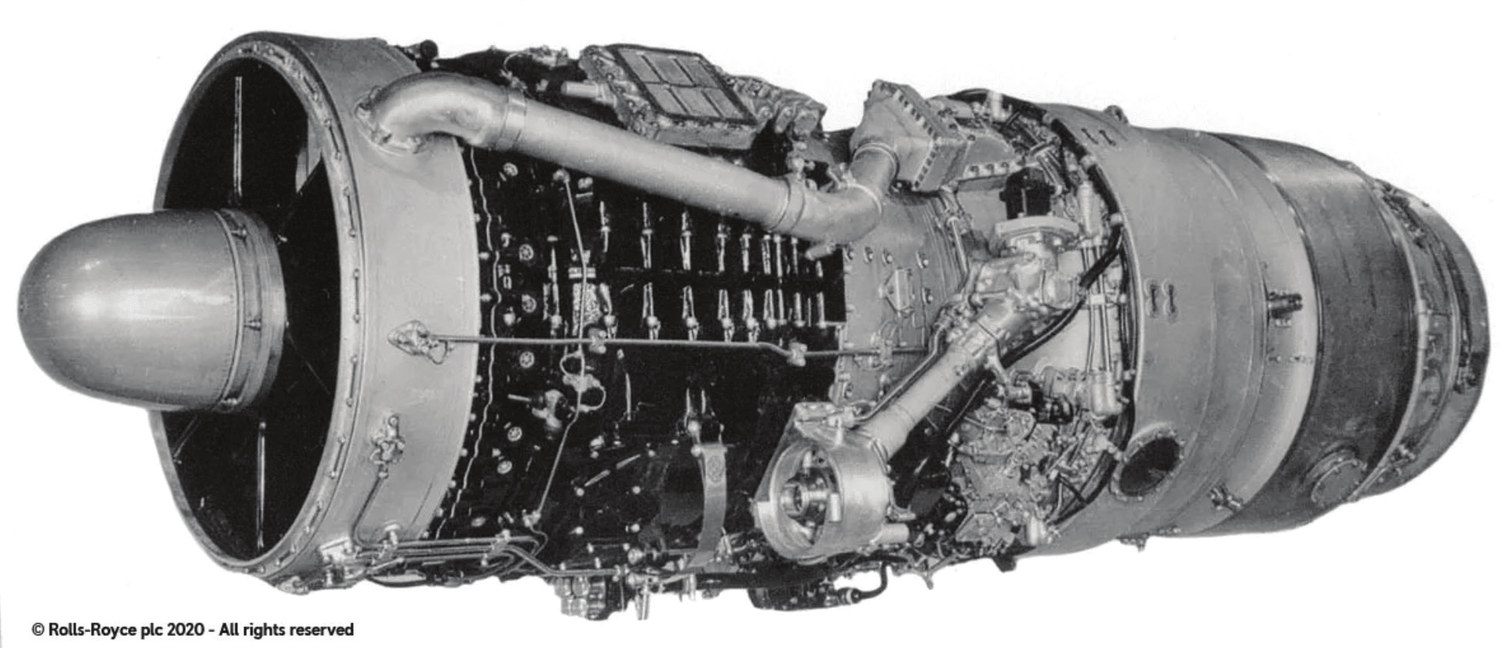

In the years after World War II, all the major engine programs started using axial compressors where the air flows in a roughly straight path, like in the Rolls-Royce Avon shown in Figure 3. The push towards bigger and more powerful engines came from the demands of a new phase in the world history: The Cold War.

Figure 3: The Rolls Royce Avon-1950

Early jet engines were used mainly for small fighter planes, because poor fuel economy made them unsuitable for larger aircraft. This marked the introduction of multi-spool engines, like the Pratt & Whitney J57 or the Bristol Olympus, the engine of the Concorde, where compressor is split into two sections, rotating at different speeds and each driven by a separate section of the turbine.

Griffith had first proposed jet engine with BPR in 1947. An engine based on this idea first ran in 1952 and evolved into the Rolls-Royce Conway having a BPR of 0.3. The Conway and its competitor the Pratt & Whitney JT8D having BPR of 0.96 (Figure 4) powered the Boeing 707 and the DC8, which opened the age of mass air travel. They also powered many military aircraft of the time.

Figure 4: Pratt and Whitney JT8D

1970’s, 80’s and 90’s has seen all major airframers contemplating wide-body commercial aircrafts capable of carrying 200 or more passengers over distances in excess of 5000 nautical miles to satisfy the increasing demand for air travel. Engine manufacturers responded by proposing new engines with high bypass ratios.

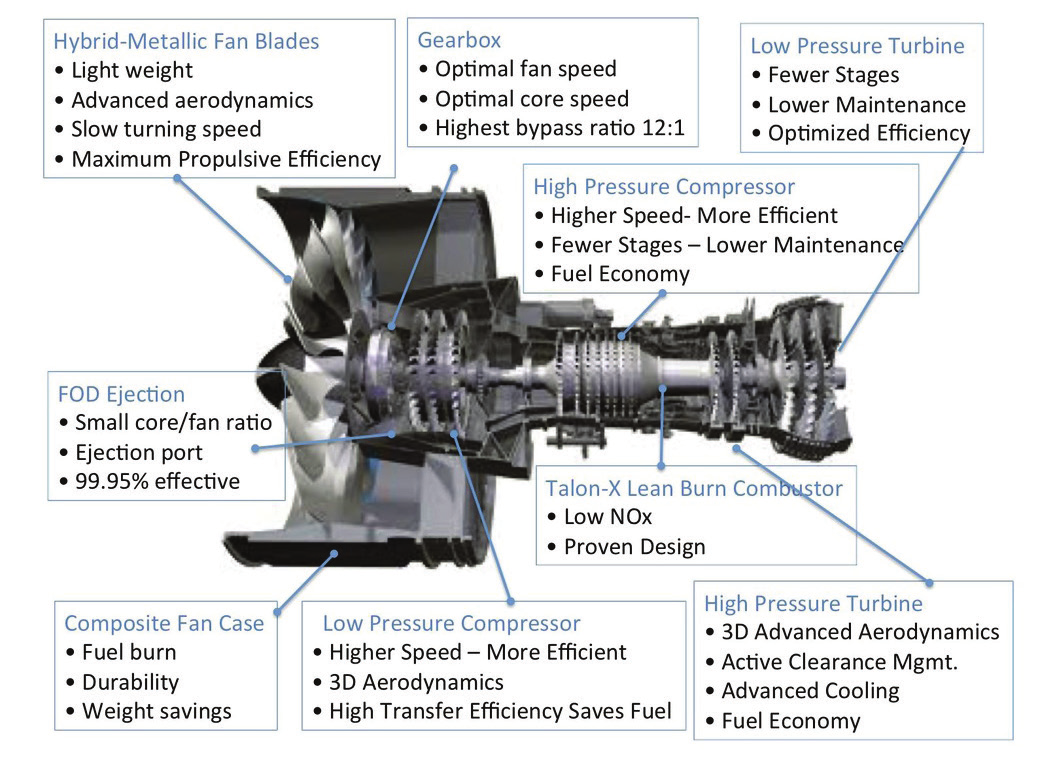

A lower fan speed allows higher bypass ratios, leading to reduced fuel consumption and much reduced noise. In a Geared Turbofan, a planetary reduction gearbox between the fan and the low-pressure shaft allows the latter to run at a higher rotational speed thus enabling fewer stages to be used in both the low-pressure turbine and the low-pressure compressor, increasing efficiency and reducing weight.

In conventional turbofans the fan tips exceed the speed of sound causing a characteristic drone, requiring sound deadening. Geared Turbofans operate the fan at sufficiently low rotational speed to avoid supersonic tip speeds and considered one of the quietest. The Turbomeca Aspin was the first Geared Turbofan to fly, powering the Fouga Gemeaux test-bed aircraft in January 1952. The ALF 502/LF 507 certified in 1980, is a Geared Turbofan engine produced by Lycoming Engines.

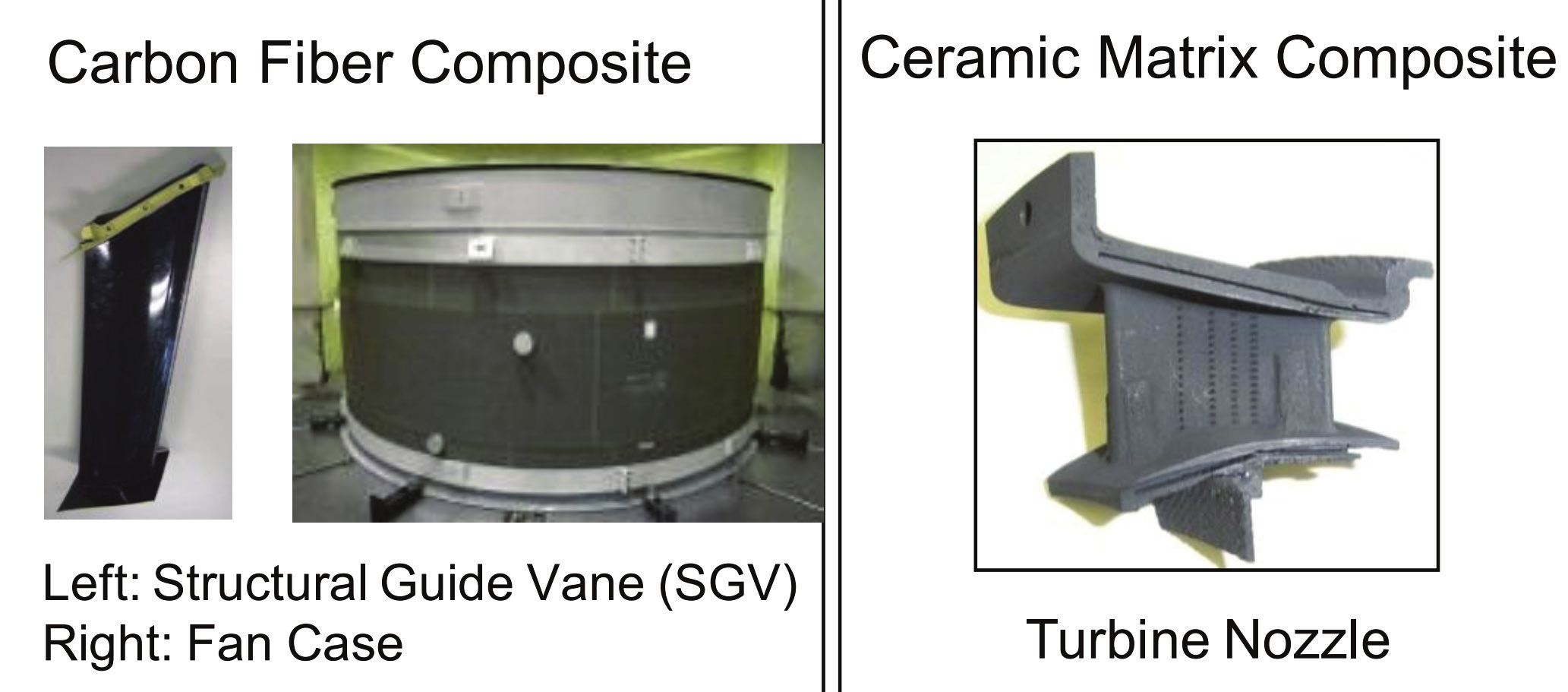

There have been significant advances in the materials used in aero engines. New materials that have low density and the ability to withstand high temperatures will contribute to improving fuel-efficiency. Ceramics have such properties but their brittleness limits their fields of application. Ceramic Matrix Composites (CMC) - ceramics reinforced with fibers can solve this issue, and are being developed as nextgeneration materials for aero engines. CMCs have been under development for more than 20 years, and will be applied to commercial fields in the near future.

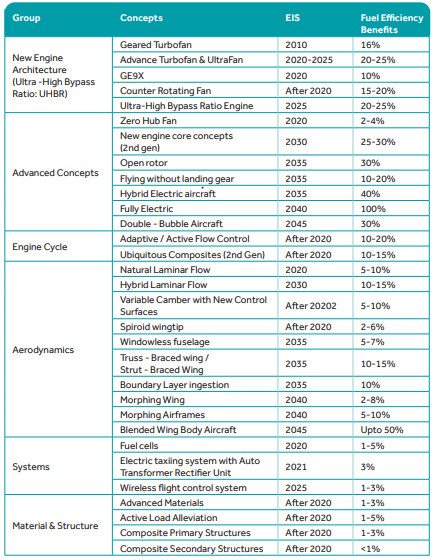

Aviation is already known as a driving force of global technology development and innovations. Current decade and beyond focus for aero engines have been towards improving and development of efficient engines by reducing emissions, fuel burn and noise levels.

To achieve specific initiatives concerning aviation environmental goals, Federal Aviation Authority (FAA) came up with five-pillar comprehensive and integrated approach per Figure 5.

Figure 5: FAA Research initiative

New engine and airframe technologies continue to play key roles in achieving aviation environment and energy goals. The FAA and other agencies support advances in engine technology and airframe configurations to lay the foundation for the next generation of aircraft. The FAA’s focus is on maturing technologies for near term application while NASA focuses on a broader range of time frames of technology development. FAA’s Continuous Lower Energy, Emissions and Noise (CLEEN) program is a NextGen effort to accelerate development and commercial deployment of environmentally promising aircraft technologies and sustainable alternative fuels with following guidelines.

Various aircraft engine manufacturers have invested in extensive research in an effort to develop new technologies that can achieve the above said guidelines. Continuous progress is being achieved in all areas of evolutionary technologies, namely aerodynamics, materials and structures, propulsion and aircraft equipment systems. Some examples of technologies which have recently made noticeable progress are: natural and hybrid laminar flow control, new high-bypass engine architectures as well as aircraft systems such as electric landing gear drives and fuel cells for onboard power generation.

One of the major introductions in the last two decades was of Geared Turbofan technology. Pratt & Whitney started to test geared design in 1993 and built the first production Geared Turbofan in 1998, with the PW8000 that had 11:1 bypass ratio but the project was abandoned. However, Pratt & Whitney re-initiated their studies in early 2000 originally known as the Advanced Technology Fan Integrator (ATFI) and later the Geared Turbofan (GTF).

The PW1000G GTF engine (Figure 6) with a BPR 12.5:1 and thrust 35,000 lbf first entered commercial use in Jan 2016 with Lufthansa's first commercial Airbus A320neo flight. The 30,000-horsepower (22,000-kilowatt) gearbox is designed as a lifetime item with no scheduled maintenance other than changing oil. The fan has 20 blades, down from 36 in the CFM56-5B that belongs to the same class. This engine family introduced the first application of aluminum fan blades. Because use of a gearbox resulted in slower fan speeds, the tensile stresses on the blades were reduced, which meant that newer high-strength alloys of aluminum could meet the blades' strength requirements not needing for blades made of titanium.

Figure 6: Pratt & Whitney GTF engine cross section

Figure 6: Pratt & Whitney GTF engine cross section

The GTF engine has achieved a 50% reduction in NOx emissions, a 75% reduction in noise footprint, and a 16% reduction in fuel consumption

In 2010, Pratt & Whitney launched the development of an ultra-high-bypass version, with a ratio significantly higher than PW1000G to improve fuel consumption by 20% compared to a CFM56-7 and reduced noise relative to the FAA's goal by 25 dB. It’s currently undergoing testing and could power the Boeing New Midsize Airplane in the mid-2020s and would compete against the Rolls-Royce UltraFan and a CFM LEAP higher-thrust version.

Rolls Royce “UltraFan” has a variable pitch fan system aims for a 15:1 BPR, 100,000 lbf thrust, 25% improvement in fuel burn and is expected by 2025. It will use carbon fiber-reinforced polymer (CFRP) composite fan blades instead of its usual hollow titanium blades saving 750 lb per engine. Also uses Advanced ceramic matrix composite (CMC) components that operate more effectively in high pressure turbine temperatures. The variable pitch fan will facilitate low pressure ratio fan operability and avoids the need for a thrust reverser. Each fan blade has a digital twin that stores real-life test data, allowing engineers to predict in-service performance.

CFMs LEAP was introduced in 2016 with 10:1 BPR, 35,000 lbf thrust and 16% fuel efficiency. Fan blades are manufactured from 3D woven RTM (Resin Transfer Molding) carbon fiber composite. This technology results not only in lightweight but also strong enough to support the weight of a wide-body airplane. It is the first engine to use additive manufacturing to “grow” complex, fully dense yet lighter engines. Its fuel nozzles are 25% lighter and five times more durable. It features Twin-Annular, Pre-Mixing Swirler Combustor (TAPS II) that reduces NOx emissions by 50%. The debris rejection system provides the best erosion protection, preventing sand, dirt, and other harmful items from reaching the core resulting in highly durable, more efficient engine.

Biofuels are biomass-derived fuels, from plants or waste; depending on which type of biomass is used, they could lower CO₂ emissions by 20–98% compared to conventional jet fuel. GE partnered with Boeing & Virgin Atlantic for first test flight using blended biofuel was in 2008, and in 2011 blended fuels with 50% biofuels were allowed in commercial flights. Pure biofuels that aren't mixed with petroleum and don't contain paraffin-based additives may cause rubber seals and hoses to shrink. So far close to 300,000 flights have flown on a mixture of sustainable aviation fuel (SAF) and regular jet fuel.

Hydro processed Esters and Fatty Acids Synthetic Paraffinic Kerosene (HEFA-SPK) is a specific type of hydrotreated vegetable oil fuel used in aviation. As of 2020 this is the only mature technology because of its sustainability. Though these alternative fuels are created from renewable sources, drop-in fuels mimic the chemistry of petroleum jet fuel and can be used in today's aircraft and engines without modification and provide the same level of performance and safety as today's petroleum-derived jet fuel. Rolls-Royce in April 2021 successfully tested with 100% SAF in its business jet engine Pearl 700. This test will help lay the groundwork for moving such fuels toward certification.

Airbus in September 2020 unveiled the zeroemission hydrogen commercial aircraft concept known as ZEROe. It includes three concepts viz., turbofan, turboprop, and blended-wing body where two hybrid hydrogen engines provide thrust. In the turbofan & turboprop configurations, the liquid hydrogen storage is located behind the rear pressure bulkhead. Whereas In blended wing configuration the same is located underneath the wings. These could enter service by 2035.

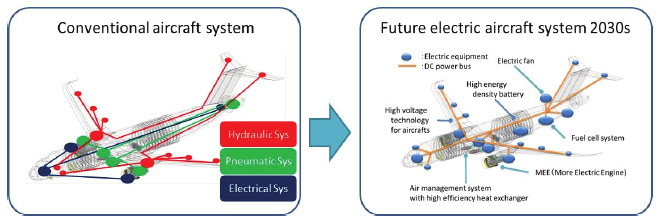

In the not-too-distant future, hybrid-electric and fully electric aircraft will revolutionize air travel. More electric architecture for aircraft & propulsion (MEAAP) focuses on the significant improvement in fuel efficiency by optimizing the aircraft system considering propulsion, thermal management and electrical power management as shown in Figure 7. By replacing traditional hydraulic and pneumatic systems with electric systems, we can reduce bleed air required from the engine and enable greater efficiency and lower fuel consumption. A study conducted by UTC indicate that commercial electric and hybrid electric propulsion could reduce aircraft noise by up to 85%, can improve fuel consumption by up to 40%, can reduce carbon dioxide emissions by more than 20% and reduce airline operating and maintenance costs by up to 20%.

Figure 7: A concept of MEAAP

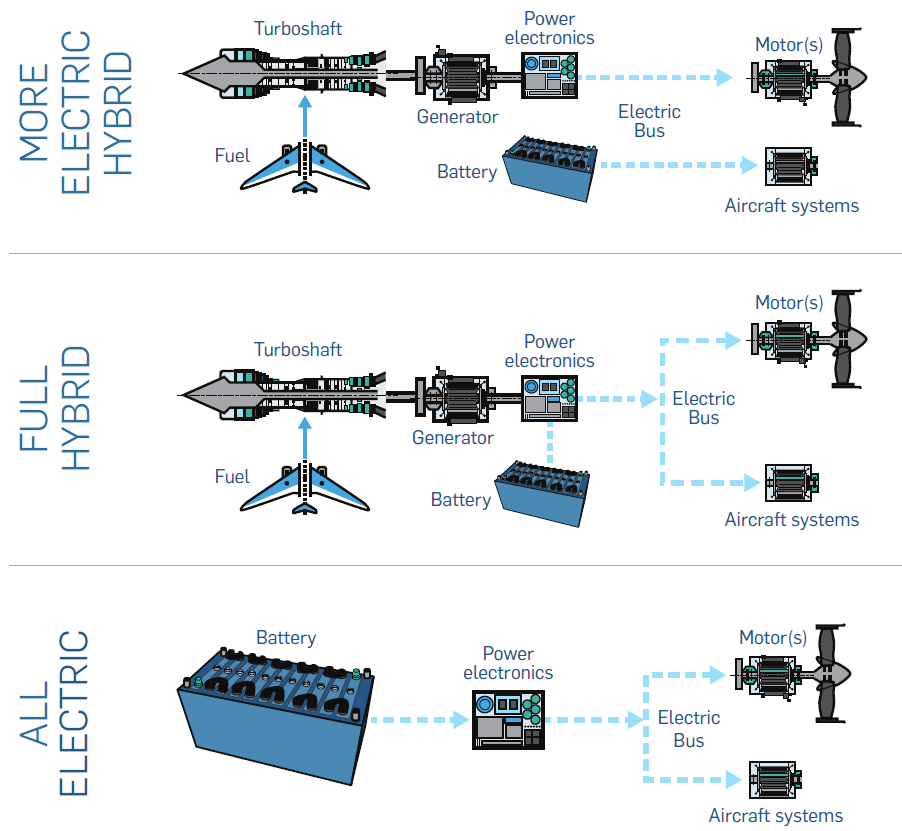

In the short term, we will probably witness a ‘More Electric-Hybrid’ commercially sized aircraft rather than an ‘All-Electric’ alternative. This ‘More Electric-Hybrid’ version could deliver real benefits through reduced emissions and allow for the development of motors and power electronics for the transition to fully electric operation. Figure 8 shows a visual of hybrid powered solution

Figure 8: MEAAP to Electric conversion

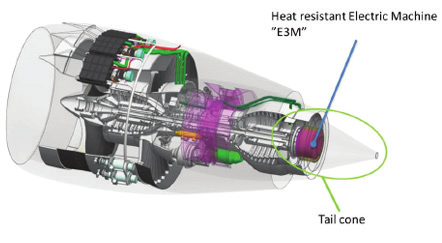

Ishikawajima-Harima Heavy Industries (IHI-Japan) developed an engine embedded electric machine (250kW) that can be mounted inside the tail cone located in the aircraft jet engine rear-end in cooperation with domestic companies, and successfully completed the evaluation testing in February 2020. The cutting-edge technology enables the high-power density and heat resistant generator, including pre-shaped and weldjointed windings with 5720 F high heatresistant insulation coating. Additionally, new cooling technology based on IHI’s expertise and experiences on the thermal, aerodynamic and structural technology for the jet engines was incorporated. See Figure 9 below.

Figure 9: Engine Embedded Electric Machine (E3M)

IHI accelerates the development of the highpower density electric machine including an actual engine demonstration, and also considers the possibility of much higher power generation system, which may be a key technology for future hybrid propulsion.

Collins Aerospace unveiled United Technologies hybrid-electric flight demonstrator. The goal is to re-engine and fly Pratt & Whitney Canada (PWC) engine on a De Havilland Dash-8 100 regional aircraft powered by a 2MW class hybridelectric propulsion system.

Eviation, a startup company based in Israel, unveiled its all-electric light aircraft, the “Alice Commuter”. The company describes the aircraft as using distributed propulsion with one main pusher propeller at the tail and two pusher propellers at the wingtips. A total of 6,000 lb of lithium-ion batteries provide power for the Alice, designed to carry up to nine passengers for a range of 600 miles.

Neva Aerospace, a U.K.-based aviation consortium, has unveiled its AirQuadOne commercial concept as a prototype for future personal manned aerial transportation. AirQuadOne is envisioned as a personal vertical takeoff and landing (VTOL) aircraft, powered by a battery pack compatible with electric car recharging stations via a direct wire connection, induction or battery pack switch.

Workhorse SureFly VTOL is an aircraft with eight independent motors driving a single carbon fiber propeller, a backup battery power system and a ballistic parachute to safely land in the event of emergency as the "reinvention of the helicopter." The two-seater rotorcraft features a gas engine and is designed to feature a 70-mile range. Workhorse Group also notes that it features full computer and electrical system redundancy and a flight ceiling of 4,000 feet.

Airbus, Rolls-Royce and Siemens formed a partnership with the objective to develop and build a hybrid-electric demonstrator aircraft, the E-Fan X. It uses serial hybrid-electric technology to power a 2MW electric motor, mounted on a BAe 146 flying testbed replacing one of the four gas turbine engines. The longerterm goal is to build a commercial aircraft equipped with the E-Fan X technology that can accommodate 50-100 passengers on board and fly regional and short-range routes, with an envisaged entry into service around the year 2035.

Materials technology is of fundamental importance to the gas turbine engine. Refer Figure 10 for typical materials used. The ultimate efficiency of the engine is limited by operating temperature and, consequently, it requires materials with high temperature capability. However, considering that the melting point of current superalloys is around 3,362°F, the challenge becomes finding materials that will withstand hotter temperatures; and as such, the search for new materials has come to the fore. The advent of lean-burn engines, with temperature potentials as high as 3,812°F, has helped drive demand for these new materials. To achieve higher thrust, higher operating temperatures must be realized and for higher efficiency, engines must be made significantly lighter without loss of thrust. In either case, new families of materials need to be developed that have higher melting points and greater intrinsic strength.

Figure 10: Typical materials used in aero engine

Figure 10: Typical materials used in aero engine

There is a revolution underway in aircraft manufacturing today and it can be summed up in one word: composites. There are many good reasons for aircraft manufacturers to use composites and for airlines to want composites to be used in their fleets. Many composite materials achieve relatively greater strength characteristics compared with traditional metallic materials, reducing aircraft weight and thus reducing fuel cost per passenger carried. Composites are more resistant than metal to fatigue from repeated take off/landing cycles, resulting in fewer costly inspections over the aircraft’s lifespan

Advanced composites made from highperformance ceramic matrix composites (CMCs), metal matrix composites (MMCs), and fiber-reinforced polymers (FRPs) are used in high-performance aerospace systems to provide additional functional benefits such as temperature resistance, radar absorption, and flutter suppression.

CMCs are as tough as metals, are just one-third the weight of nickel alloys, and can operate at 2,372°F. Ability to withstand extreme temperatures requires less cooling air to be diverted from the thrust; as a result, engines run at higher thrust. Additionally, engines run hotter, combusting fuel more completely, reducing fuel consumption, and emitting fewer pollutants. Most of the current CMC developments in aircraft engines are primarily for static components, such as shrouds and combustor liner. There can be a healthy surge in the demand for CMC parts in rotational components in the coming years. Rolls-Royce, has been working on silicon carbide (SiC) CMCs that can endure high temperatures of 3,452°F. These are also two-thirds lighter than traditional nickel-based alloys.

Carbon fiber is a material made of carbon atoms that are arranged into long, thin crystals. The arrangement of these crystals makes carbon fiber extremely strong for its thickness, which is less than that of a human hair. Carbon fiber is a unique material that can be molded with epoxy into nearly any shape, including shapes that can’t be achieved with metals, or without welding several pieces together and creating weak points. Advantages of carbon fiber is that it is light weight and incredibly resistant to breakage under tension. Refer Figure 11 for carbon fiber and CMC parts used on PW1100G engine.

Figure 11: CFC and CMC parts used on PW1100G

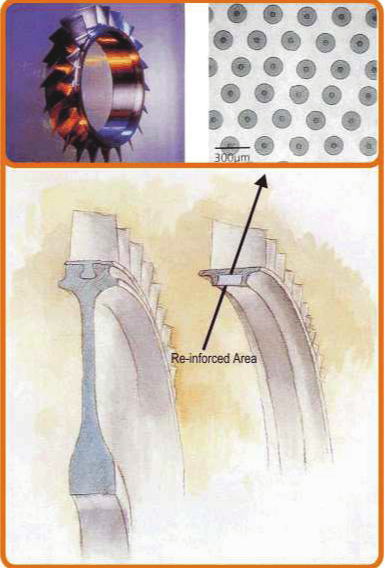

Metal Matrix composites (MMC), the system of most relevance to aircraft engines is continuous ceramic fiber-reinforced titanium. A prime aeroengine application of MMCs will be in compressor discs and drums, in which the very high performance of the fibers can be exploited to give substantial reductions in weight (in excess of 70%) without the need to introduce the fibers into complex shapes. Savings in weight come from the elimination of the usual metal central web and hub, the hoop strength and stiffness being provided instead by a ring of reinforcing silicon carbide fibers, see Figure 12.

Fiber-reinforced polymers (FRPs) are advanced fibrous architectures (two-dimensional and three-dimensional woven, knitted, and braided) which are used as preforms of composite materials.

Sandwich composites made of advanced 3D sandwich fibrous architectures with integrated face and core solve the delamination problems. These can be preferably utilized in the future for aerospace parts.

High shear and torsional strength and stiffness, high transverse strength and modulus, damage tolerance and fatigue life, notch insensitivity, high fracture toughness, and the possibility to develop complex and near-net-shape composites are some important advantages of braided composites. The rocket nozzle, fan blade containment case, aircraft propellers, and stator vanes are some aerospace structural parts constructed using braided composites.

While a considerable amount of weight reduction has been achieved through the use of composite materials and light metal alloys, researchers are looking into revolutionary materials that would offer even better weight efficiency and increased aircraft performance. Auxetic composites, Nanomaterials, Hybrid multiscale composites, Self-sensing composites, Intermetallic and shape memory nickel titanium alloy are a few materials being researched.

Figure 12: MMC bladed ring

Cyient supports turbine engine OEMs in deploying innovative technology solutions for aircraft engine components and modules. Expertise lies in the design and ownership of actuations, bearings, rotors, cases, lube systems, dynamic loads, and electric propulsion systems for aircraft. Cyient subject matter expertise helps continually explore opportunities for high-efficiency aerodynamic blade profiles, more efficient thermal dissipation, and greater fatigue life. Cyient also integrates digital transformation into aero engine solutions to provide data-driven reliability control, predictive maintenance, and quality notification resolution.

Leveraging innovative engineering concepts and over 15 million person-hours of experience, Cyient assisted Pratt & Whitney on the design and analysis of Geared Turbofan engine from 2006 towards becoming a reality in 2016.

Growing demand for new technologies and systems has led OEMs looking for solutions and vendors that can help address challenges caused by new market shifts and stay ahead of the curve. Cyient stands at the ready to meet these new market challenges, and the company has invested its own resources to prepare in advance of these new requirements to meet these challenges.

From this report, it can be seen that a broad range of technological innovations is under development to improve aircraft fuel efficiency, reduce emissions and noise.

Historically, new technologies have offered the greatest success in reducing aviation’s environmental impacts. Sustainable alternate fuels (SAFs) are major enablers toward reaching carbon neutrality for aviation. Hydrogen is one of the few zero-carbon solutions for aviation, if produced sustainably. That’s why the aviation industry is investing more and more in hydrogen R&D, and why we may see hydrogen-fueled aircraft enter into service in the next 15 to 25 years.

Since the early jet age, aircraft fuel burn per passenger-km has been reduced by over 70%, and there is potential to reduce today’s fuel burn by another 30% approximately without going to radically different aircraft configurations and propulsion. The potential of these evolutionary technologies, mostly in the areas of aerodynamics, lightweight materials and structures, new engine architecture and aircraft systems, will however diminish over the years. Evolutionary technologies will thus not be enough to keep a similar emissions reduction rate as today and contribute significantly to the 2050 emissions reduction goal, more radical configuration changes will be required in addition.

With rich experience and domain expertise, Cyient helps A&D OEMs and Tier 1 suppliers transform their product life cycle and engineering solutions that adhere to rigorous compliance systems that meet the wide spectrum of security parameters, including the International Traffic in Arms Regulations (ITAR) and nation-specific restrictions. We also have Design Approval from the Centre for Military Airworthiness & Certification (CEMILAC), a laboratory of the Indian Defense Research and Development Organization (DRDO) under the following scope: “Design, Development of Aero Structures, Aero Interiors, Aero Engines Parts and Systems, Aero Systems, and Avionics for Military Airborne Applications.” Cyient takes pride in partnering with the world’s leading A&D companies to deliver value-driven and outcomebased engineering solutions. We undertake design and system-level ownership of complex components, sub-systems, and modules to allow our customers to sustain a competitive advantage.

Cyient is well-positioned to address the megatrends of the next decade, Data AI & Platformization, Automation & Edge AI solutions. Cyient works collaboratively with our customers and partners to incorporate digital solutions into the design, build, operate, and maintain stages of their product development life cycles. We leverage big data, IoT, AR/VR, machine learning, advanced analytics, and artificial intelligence to build new business models and drive automated decision-making. We also help OEMs become more agile at manufacturing, collaborate closely in aerospace supply chain management, and deploy effective aircraft predictive maintenance solutions. Few examples include AR/ VR in Aftermarket, Data Analytics and insights of field data, Analysis of compressor using RPA, AI/ ML for automated Non conformance solutions, Digital Twin and many more. Cyient has been successfully delivering bespoke IT applications to multiple aerospace customers over the past 15 years covering areas like design automation, engineering process digitization, reliability data management, aftermarket planning, field event management, and DPHM. Our teams leverage the latest technologies to deliver these solutions at scale. From engineering quality notification resolution, to aerospace asset health monitoring and augmented reality based aircraft maintenance, we bring an innovative approach to the needs of each organization to build digital solutions and IP.

Cyient (Estd: 1991, NSE: CYIENT) is a leading global engineering and technology solutions company. We are a Design, Build, and Maintain partner for leading organizations worldwide. We leverage digital technologies, advanced analytics capabilities, and our domain knowledge and technical expertise, to solve complex business problems.

We partner with customers to operate as part of their extended team in ways that best suit their organization’s culture and requirements. Our industry focus includes aerospace and defense, healthcare, telecommunications, rail transportation, semiconductor, geospatial, industrial, and energy. We are committed to designing tomorrow together with our stakeholders and being a culturally inclusive, socially responsible, and environmentally sustainable organization.

For more information, please visit www.cyient.com

Cyient (Estd: 1991, NSE: CYIENT) is a global digital engineering and technology company.

© Cyient 2023. All Rights Reserved.