Multi-discipline engineering for Renewcell process and sustaintech plant in Sundsvall

CASE IN BRIEF

Customer: Renewcell

Project location: Sundsvall, Sweden

Year completed: 2022.

Project goal: Hundreds of millions of garments to be saved from landfill and incineration each year.

Plant type: Re-pulping of fabric for production of recycled textiles

Capacity: 60 000 ton/year

Cyient scope of services:

- Project management

- Process design

- Layout and piping design

Renewcell, a multi-award-winning sustaintech company, cooperated with Cyient regarding the production of recycled textiles in Sweden. Renewcell’s vision is to inspire an Industrial Evolution to a sustainable world by producing high quality materials from recycled textiles.

Through its patented process, Renewcell can upcycle cellulosic textile waste, such as cotton clothes, transforming it into a pristine new material called Circulose®. Fast Company named Renewcell as one of the World’s Most Innovative Companies 2021. Circulose® was also included on TIME Magazine’s list of the 100 Best Inventions 2020.

Renewcell’s product is Circulose® – a branded dissolving pulp product produced from 100% recycled textiles. Renewcell’s customers use Circulose® as a raw material to produce natural biodegradable textile fibers like viscose and lyocell. By replacing virgin textile fibers like cotton with fibers produced from Circulose®, fashion brands can reduce the climate and environmental impact caused by raw material extraction and fashion waste generation significantly. Contaminants and other non-cellulosic content are separated from the slurry. The slurry is dried to produce a pure, natural Circulose® branded dissolving pulp made from 100% recycled textiles. The sheets of Circulose® are finally packaged into bales and fed back into the textile production value chain as a replacement for virgin materials like cotton, oil, and wood.

At Renewcell’s new plant constructed in Sundsvall, Sweden, hundreds of millions of garments will be saved from landfill and incineration each year. The plant was designed and planned to be in operation in the first half of 2022. The cooperation between Cyient and Renewcell started in 2020, when a pre-study was conducted by Cyient.

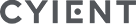

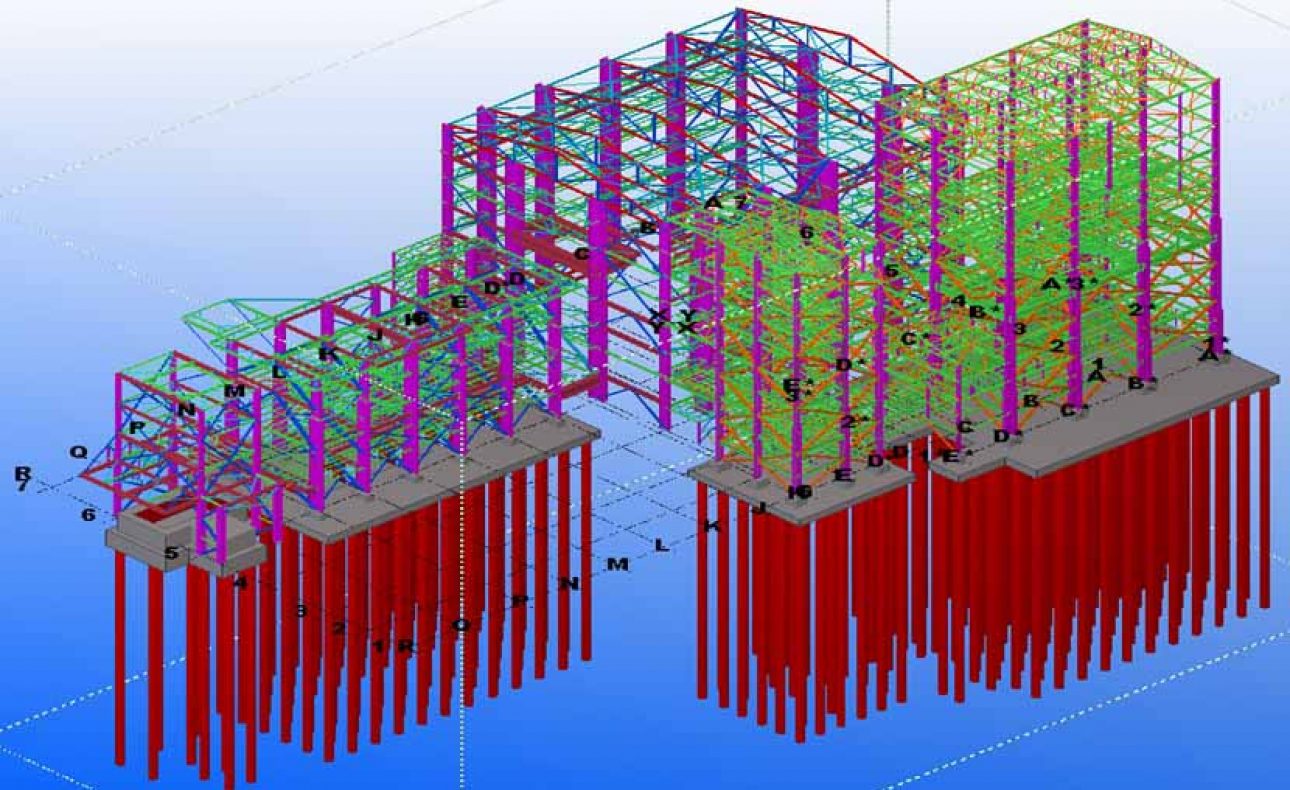

Cyient provided project management, process design, layout, and piping design for the plant in Sundsvall.

CASE IN BRIEF

Customer: Renewcell

Project location: Sundsvall, Sweden

Year completed: 2022.

Project goal: Hundreds of millions of garments to be saved from landfill and incineration each year.

Plant type: Re-pulping of fabric for production of recycled textiles

Capacity: 60 000 ton/year

Cyient scope of services:

- Project management

- Process design

- Layout and piping design

Renewcell, a multi-award-winning sustaintech company, cooperated with Cyient regarding the production of recycled textiles in Sweden. Renewcell’s vision is to inspire an Industrial Evolution to a sustainable world by producing high quality materials from recycled textiles.

Through its patented process, Renewcell can upcycle cellulosic textile waste, such as cotton clothes, transforming it into a pristine new material called Circulose®. Fast Company named Renewcell as one of the World’s Most Innovative Companies 2021. Circulose® was also included on TIME Magazine’s list of the 100 Best Inventions 2020.

Renewcell’s product is Circulose® – a branded dissolving pulp product produced from 100% recycled textiles. Renewcell’s customers use Circulose® as a raw material to produce natural biodegradable textile fibers like viscose and lyocell. By replacing virgin textile fibers like cotton with fibers produced from Circulose®, fashion brands can reduce the climate and environmental impact caused by raw material extraction and fashion waste generation significantly. Contaminants and other non-cellulosic content are separated from the slurry. The slurry is dried to produce a pure, natural Circulose® branded dissolving pulp made from 100% recycled textiles. The sheets of Circulose® are finally packaged into bales and fed back into the textile production value chain as a replacement for virgin materials like cotton, oil, and wood.

At Renewcell’s new plant constructed in Sundsvall, Sweden, hundreds of millions of garments will be saved from landfill and incineration each year. The plant was designed and planned to be in operation in the first half of 2022. The cooperation between Cyient and Renewcell started in 2020, when a pre-study was conducted by Cyient.

Cyient provided project management, process design, layout, and piping design for the plant in Sundsvall.