Supported 400+ aerospace suppliers in delivery assurance, order placement, and First Article Inspection (FAI) activities

Design-led manufacturing (DLM) with technology as the enabler, is transforming the A&D value chain from delivering discrete service offerings to delivering full systems build and integration. A&D OEMs are looking for partners who can provide cost-effective manufacturing solutions with agility and scalability.

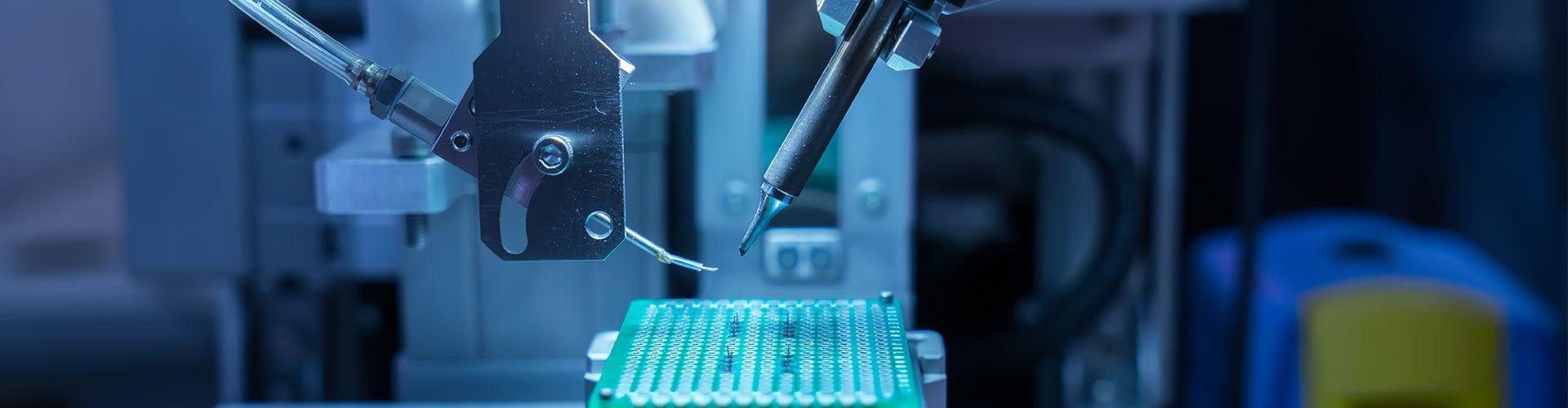

Cyient offers full-scale electronic and mechanical aerospace manufacturing engineering solutions—from conceptualization to design and maintenance. We partner with our clients to provide complete product life cycle solutions with complete commitment to quality. Our DLM expertise spans, but is not limited to, electronics manufacturing, wire cable harness, PCB assembly, in-circuit testing, aerospace CNC machining, precision tooling, vibration testing, and first article inspection.

The impetus for A&D OEMs is to identify a different approach to new product innovation that will help them realize their business objectives. Learn how we deliver new product innovation with our advanced manufacturing techniques.

Our integrated design, engineering, and manufacturing capabilities combined with expertise in co-developing solutions customized to the A&D industry have enabled us to deliver cutting edge solutions to our customers. Our portfolio covers the design, build, and maintain phases of the product life cycle to provide OEMs with a single source for optimizing aerospace parts manufacturing processes.

Our electronic manufacturing facility is among the first to earn the AS9100 aerospace certification and the first in India to obtain the National Aerospace and Defense Contractors Accreditation Program (NADCAP) certification for Circuit Card Assembly (CCA). We have the experience and expertise to handle high and low volume opportunities while optimizing speed, quality, and cost to differentiate ourselves from other suppliers.

Our DLM capabilities further enhance our position as a partner for defense offset requirements and the “Make in India” initiative. Our expertise in advanced aerospace parts manufacturing and material alternatives for product optimization provide a differentiated value proposition to the aerospace and defense segment in avionics, mechanical systems, and aftermarket solutions.

Find out more about how you can maximize impact through our services and solutions.*

*Suppliers, job seekers, or alumni, please use the appropriate form.

Cyient (Estd: 1991, NSE: CYIENT) is a global digital engineering and technology company.

© Cyient 2023. All Rights Reserved.